Pressure Control Using a Pinch Valve: Non-Linear Control Output

- Overview

- Running the Scripts

- Code Example 1: Pressure Model Simulation

- Code Example 2: Complex PID Controller for the Pinch Valve

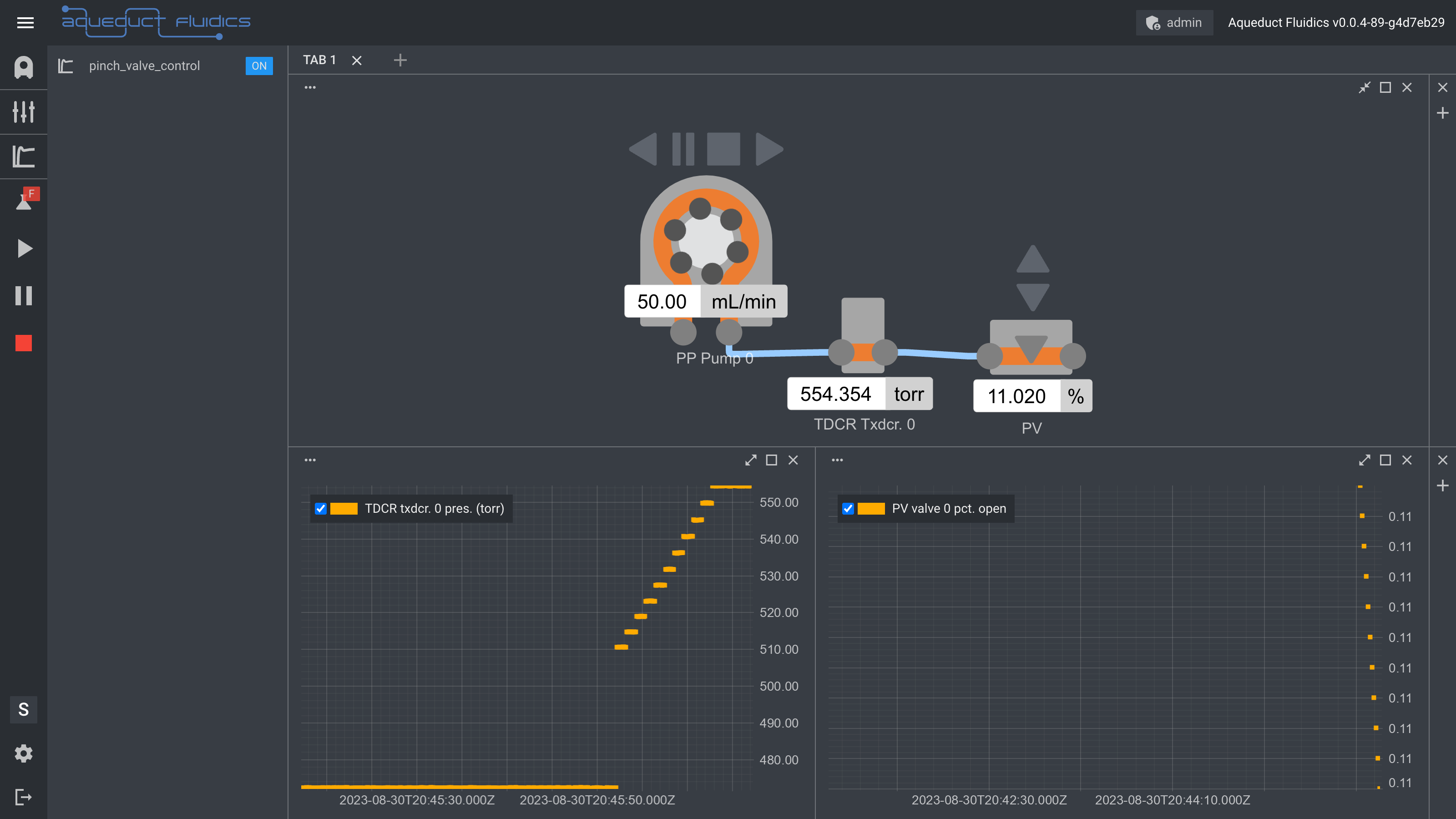

Overview

This guide aims to demonstrate how to implement a pressure control system using a Pinch Valve. The complexity lies in the unique characteristics of a Pinch Valve, which squeezes an elastomeric tube to regulate back pressure. The valve's flow coefficient (Cv) varies in a non-linear fashion with the valve's plunger position (percentage of travel, from full close to full open). This adds an extra layer of complexity to the control system.

As the valve pinches the tube, the effective opening size and shape change non-linearly. Consequently, the Cv (valve flow coefficient) also changes non-linearly with the percentage of valve opening.

Addressing Non-Linearity through Complex PID Scheduling

To manage this non-linearity, the controller must be designed to operate differently in various regions of operation. Specifically, when the total percentage of the valve's opening is small, the maximum control output change (delta_limit) has to be very small to avoid overshooting or other adverse effects.

The PID controller code includes a scheduling system that changes the control parameters based on the operating conditions. Here's a snippet of that part:

# Define multiple schedules with different controller settings

for error_range, control_range, delta_limit, dead_zone in [

((-50, 50), None, 0.00005, 10),

((-250, 250), None, 0.0005, None),

((-10000, 0), None, 0.05, None),

(None, (0, 0.3), 0.020, None),

(None, None, 0.050, None),

]:

params = ScheduleParameters()

params.kp = -1.0

params.dead_zone = dead_zone

params.delta_limit = delta_limit

constraints = ScheduleConstraints()

constraints.error = error_range

constraints.control = control_range

sched = Schedule(params, constraints)

p.add_schedule(sched)

This scheduling system allows the controller to operate with different settings, including a dead zone, delta limits, and control ranges, depending on the state of the system. This makes it adaptable and more accurate, particularly when dealing with the non-linear characteristics of the Pinch Valve.

Running the Scripts

To run the simulation and control, you'll need to execute two separate Python scripts in sequence:

-

Pressure Model Simulation (

model.py): First, run themodel.pyscript to simulate the pressure control system. Execute this command in your terminal:python3 examples/pid/pinch_valve/model.py -r 0 -

Complex PID Controller (

pid.py): Oncemodel.pyis running, execute thepid.pyscript. This will set up a PID controller to regulate the Pinch Valve based on the pressure readings. Run this command:python3 -i examples/pid/pinch_valve/pid.py

Note: It's crucial to run model.py before executing pid.py to ensure the simulation environment is initialized correctly.

Code Example 1: Pressure Model Simulation

Imports

import argparse

import time

from aqueduct.core.aq import Aqueduct

from aqueduct.core.aq import InitParams

from aqueduct.devices.base.utils import DeviceTypes

from aqueduct.devices.pressure.transducer import PressureTransducer

from aqueduct.devices.pressure.transducer import PressureUnits

from aqueduct.devices.pump.peristaltic import PeristalticPump

from aqueduct.devices.valve.pinch import PinchValve

The PressureModel Class

The PressureModel class simulates a pressure control system using various devices such as a pump, pinch valve, and pressure transducer.

class PressureModel:

def __init__(self, pump: PeristalticPump, pinch_valve: PinchValve, transducer: PressureTransducer, aqueduct: "Aqueduct"):

self.pump = pump

self.pv = pinch_valve

self.tdcr = transducer

self.aq = aqueduct

# ...

Here's the full code for the model:

"""

Demo code demonstrating pressure estimation using a simple model for Aqueduct devices.

"""

# Import necessary modules

import argparse

import time

from aqueduct.core.aq import Aqueduct

from aqueduct.core.aq import InitParams

from aqueduct.devices.base.utils import DeviceTypes

from aqueduct.devices.pressure.transducer import PressureTransducer

from aqueduct.devices.pressure.transducer import PressureUnits

from aqueduct.devices.pump.peristaltic import PeristalticPump

from aqueduct.devices.valve.pinch import PinchValve

class PressureModel:

"""

Simple model for estimating pressures in a filtration process using Aqueduct devices.

"""

filtration_start_time: float = None

filter_cv_retentate: float = 60

def __init__(

self,

pump: PeristalticPump,

pinch_valve: PinchValve,

transducer: PressureTransducer,

aqueduct: "Aqueduct",

):

self.pump = pump

self.pv = pinch_valve

self.tdcr = transducer

self.aq = aqueduct

@staticmethod

def calc_pv_cv(PV) -> float:

"""

Calculate the Cv of the pinch valve.

:param PV: Pinch valve position.

:type PV: float

:return: Cv of the pinch valve.

:rtype: float

"""

if PV < 0.35:

return max(100 - (1 / PV**2), 1)

else:

return 100

def calc_p1(self, R1, PV) -> float:

"""

Calculate the pressure drop between retentate and permeate.

:param R1: Flow rate in the pass-through leg of the TFF filter.

:type R1: float

:param PV: Pinch valve position.

:type PV: float

:return: Pressure drop between retentate and permeate.

:rtype: float

"""

try:

return 1 / (PressureModel.calc_pv_cv(PV) * 0.865 / R1) ** 2

except ZeroDivisionError:

return 0

def calc_pressures(self):

"""

Calculate and update the pressures using the model equations.

"""

p1 = self.calc_p1(self.pump.live[0].ml_min, self.pv.live[0].pct_open)

p1 = min(p1, 50)

self.tdcr.set_sim_values(values=(p1,), units=PressureUnits.PSI)

if __name__ == "__main__":

# Parse the initialization parameters from the command line

params = InitParams.parse()

# Initialize the Aqueduct instance with the provided parameters

aq = Aqueduct(

params.user_id,

params.ip_address,

params.port,

register_process=params.register_process,

)

# Perform system initialization if specified

aq.initialize(params.init)

# Set a delay between sending commands to the pump

aq.set_command_delay(0.05)

parser = argparse.ArgumentParser()

parser.add_argument(

"-c",

"--clear",

type=int,

help="clear and create the setup (either 0 or 1)",

default=1,

)

args, _ = parser.parse_known_args()

clear = bool(args.clear)

# Define names for devices

PUMP_NAME = "PP"

XDCR_NAME = "TDCR"

PV_NAME = "PV"

if clear:

# Clear the existing setup and add devices

aq.clear_setup()

aq.add_device(DeviceTypes.PERISTALTIC_PUMP, PUMP_NAME, 1)

aq.add_device(DeviceTypes.PRESSURE_TRANSDUCER, XDCR_NAME, 1)

aq.add_device(DeviceTypes.PINCH_VALVE, PV_NAME, 1)

# Retrieve the setup to confirm the added devices

aq.get_setup()

# Retrieve device instances

pp: PeristalticPump = aq.devices.get(PUMP_NAME)

tdcr: PressureTransducer = aq.devices.get(XDCR_NAME)

pv: PinchValve = aq.devices.get(PV_NAME)

# Create an instance of the PressureModel

model = PressureModel(pp, pv, tdcr, aq)

# Continuous pressure calculation loop

while True:

model.calc_pressures()

time.sleep(0.1)

Code Example 2: Complex PID Controller for the Pinch Valve

Imports

from aqueduct.core.aq import Aqueduct

from aqueduct.core.aq import InitParams

from aqueduct.core.pid import Pid

from aqueduct.core.pid import Schedule

from aqueduct.core.pid import ScheduleConstraints

from aqueduct.core.pid import ScheduleParameters

from aqueduct.devices.pressure.transducer import PressureTransducer

from aqueduct.devices.pump.peristaltic import PeristalticPump

from aqueduct.devices.valve.pinch import PinchValve

Device Retrieval

pp: PeristalticPump = aq.devices.get(PUMP_NAME)

tdcr: PressureTransducer = aq.devices.get(XDCR_NAME)

pv: PinchValve = aq.devices.get(PV_NAME)

PID Controller Setup

The PID controller is set up with multiple schedules to adapt to the system's non-linear nature.

# Define PID controller parameters

process = tdcr.to_pid_process_value(index=0)

control = pv.to_pid_control_output(index=0)

p = Pid(500)

Here's the full code for PID control:

"""

Demonstration of setting up a PID controller with Aqueduct devices.

"""

# Import necessary modules

from aqueduct.core.aq import Aqueduct

from aqueduct.core.aq import InitParams

from aqueduct.core.pid import Pid

from aqueduct.core.pid import Schedule

from aqueduct.core.pid import ScheduleConstraints

from aqueduct.core.pid import ScheduleParameters

from aqueduct.devices.pressure.transducer import PressureTransducer

from aqueduct.devices.pump.peristaltic import PeristalticPump

from aqueduct.devices.valve.pinch import PinchValve

# Parse the initialization parameters from the command line

params = InitParams.parse()

# Initialize the Aqueduct instance with the provided parameters

aq = Aqueduct(params.user_id, params.ip_address, params.port)

# Perform system initialization if specified

aq.initialize(params.init)

# Set a delay between sending commands to the pump

aq.set_command_delay(0.05)

# Define names for devices

PUMP_NAME = "PP"

XDCR_NAME = "TDCR"

PV_NAME = "PV"

# Retrieve the setup to confirm the added devices

aq.get_setup()

# Retrieve device instances

pp: PeristalticPump = aq.devices.get(PUMP_NAME)

tdcr: PressureTransducer = aq.devices.get(XDCR_NAME)

pv: PinchValve = aq.devices.get(PV_NAME)

# Define PID controller parameters

process = tdcr.to_pid_process_value(index=0)

control = pv.to_pid_control_output(index=0)

p = Pid(500)

# Define multiple schedules with different controller settings

for error_range, control_range, delta_limit, dead_zone in [

((-50, 50), None, 0.00005, 10),

((-250, 250), None, 0.0005, None),

((-10000, 0), None, 0.05, None),

(None, (0, 0.3), 0.020, None),

(None, None, 0.050, None),

]:

params = ScheduleParameters()

params.kp = -1.0

params.dead_zone = dead_zone

params.delta_limit = delta_limit

constraints = ScheduleConstraints()

constraints.error = error_range

constraints.control = control_range

sched = Schedule(params, constraints)

p.add_schedule(sched)

# Set output limits for the PID controller

p.output_limits = (0.1, 1)

# Create a PID controller instance using Aqueduct

pid = aq.pid_controller("pinch_valve_control", process, control, p)