Aqueduct Fluidics makes automation more accessible for benchtop-scale applications in research and development and in small scale production.

Our platform empowers users to conceive, design, simulate, and deploy complex systems with confidence.

The platform simplifies system integration by handling challenging elements such as communication and command timing, user interfaces, and data persistence. Users can focus on their specific protocols while the platform takes care of the underlying complexities.

Key Benefits:

-

Simple, Flexible Scripting

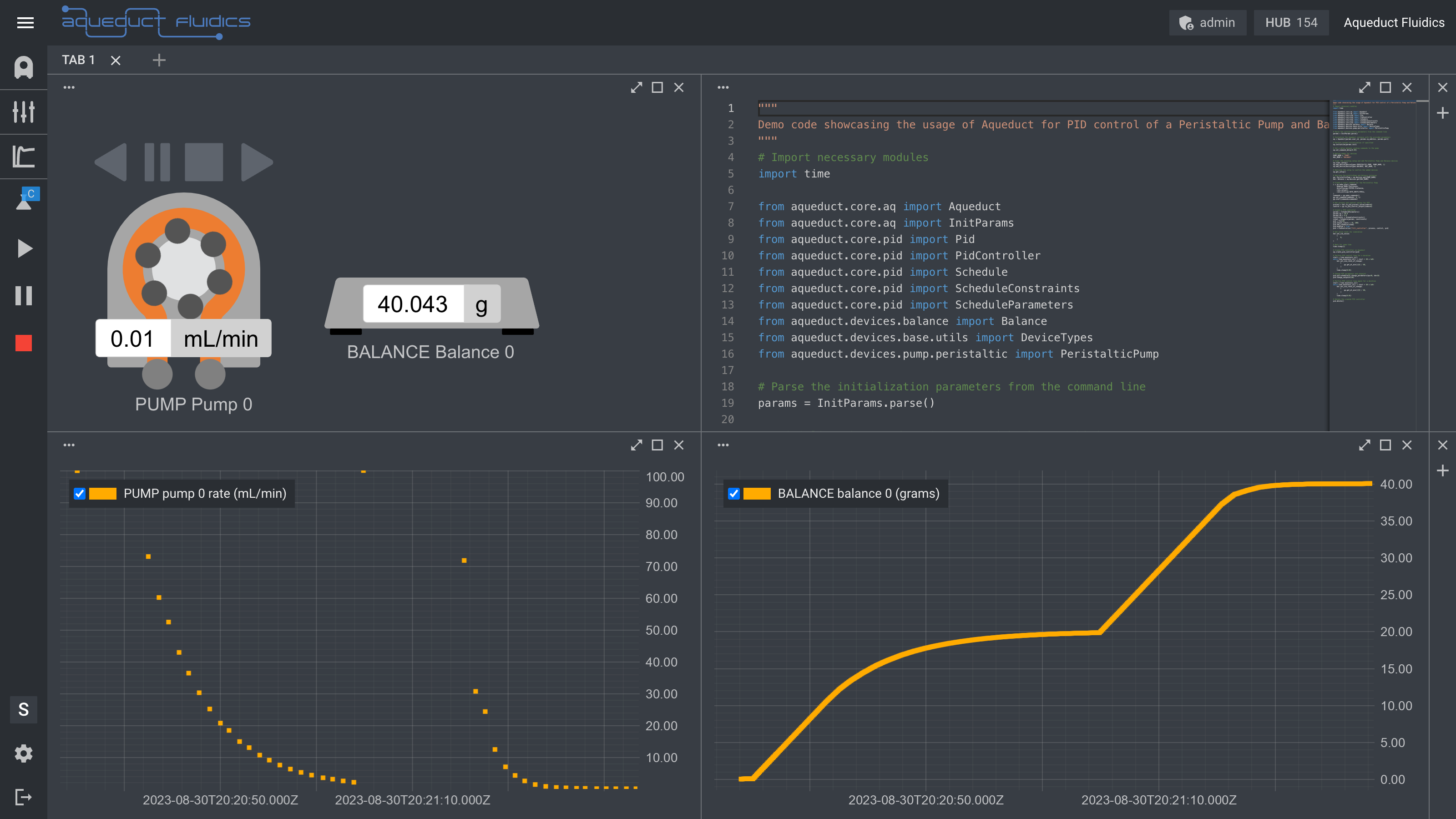

Aqueduct Recipes are written in Python (3.7+), the widely adopted scripting language. Leveraging the power of Python's standard library and the Aqueduct API, users can easily program processes without sacrificing the flexibility required for their specific applications.

-

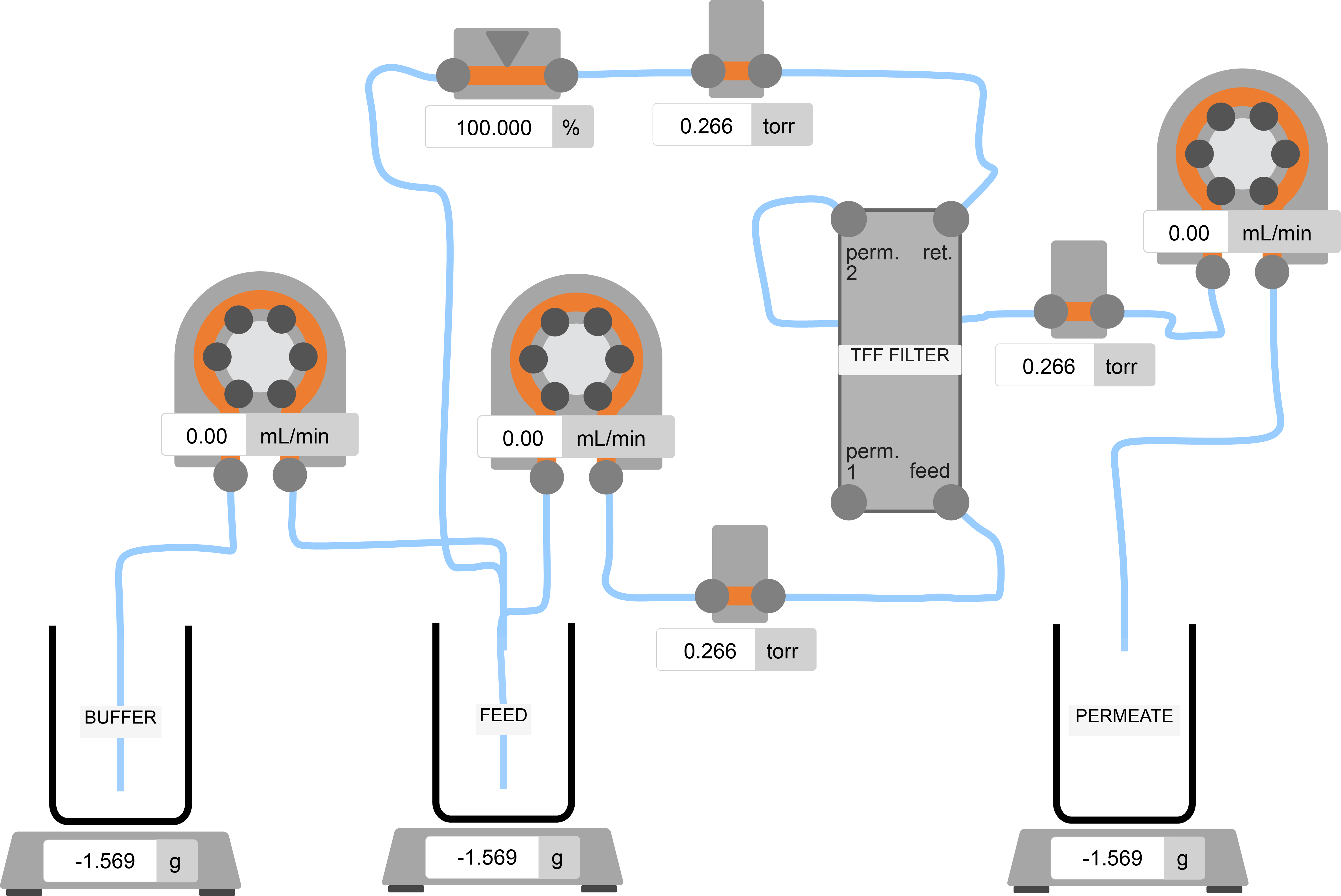

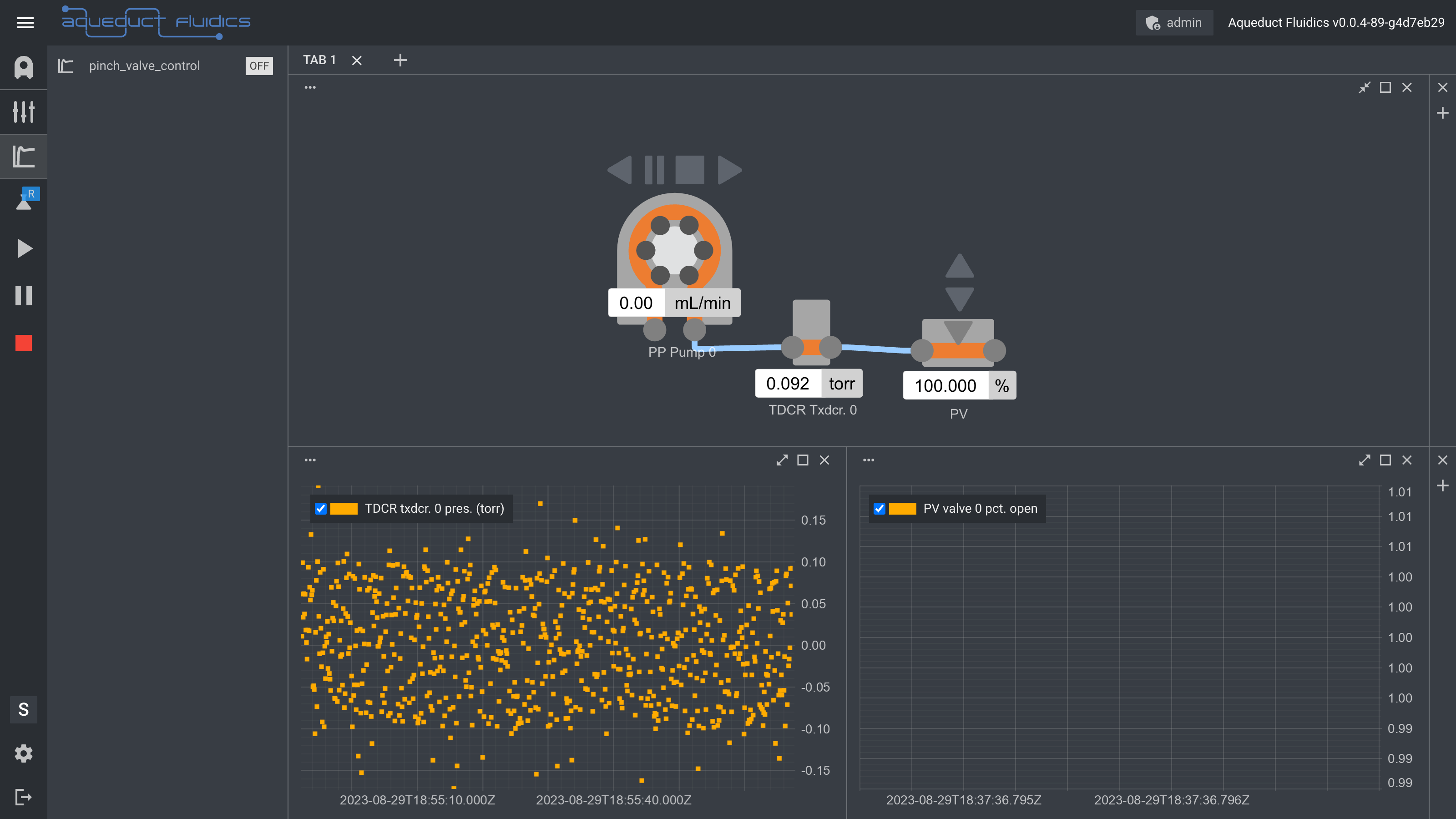

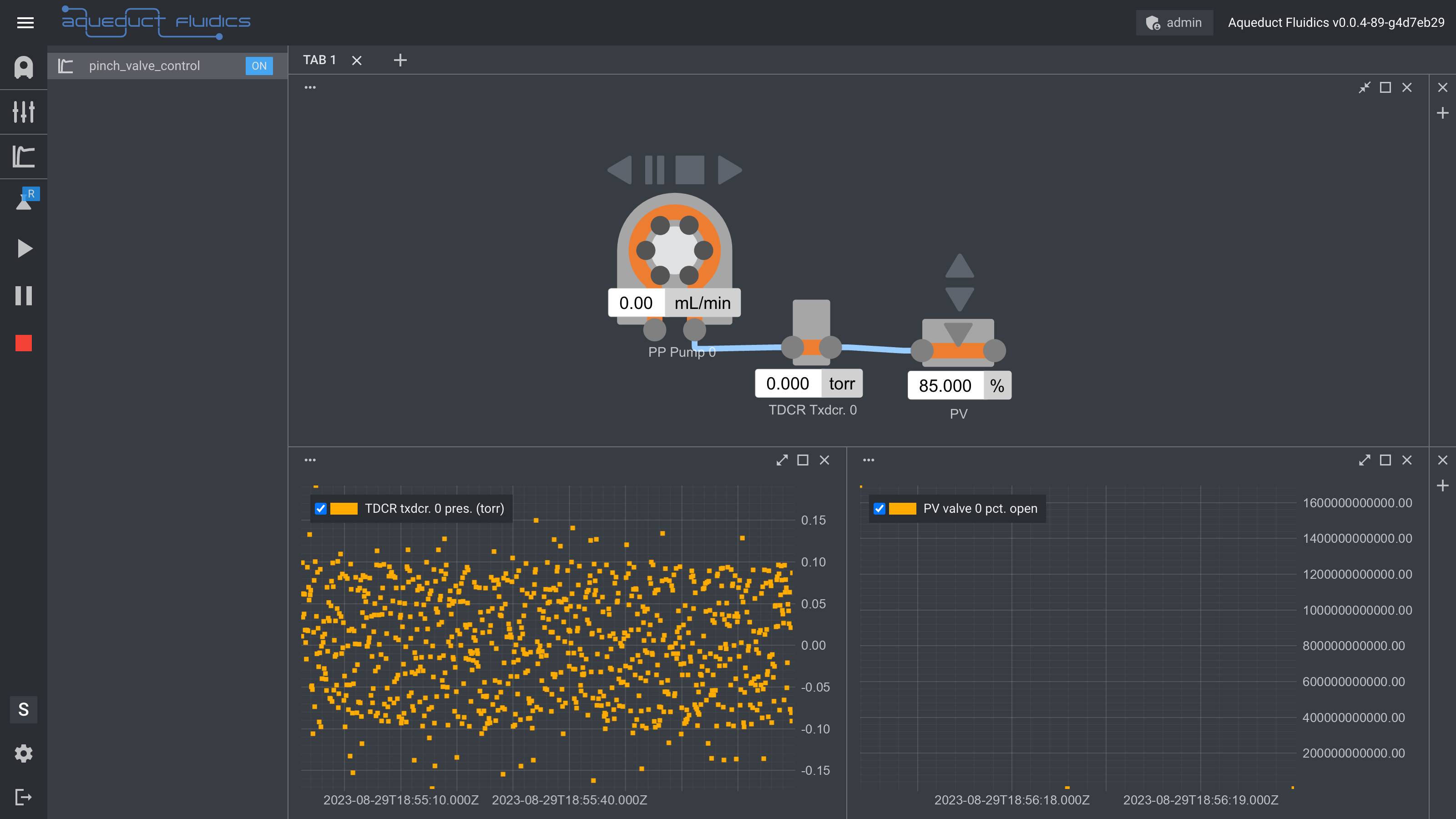

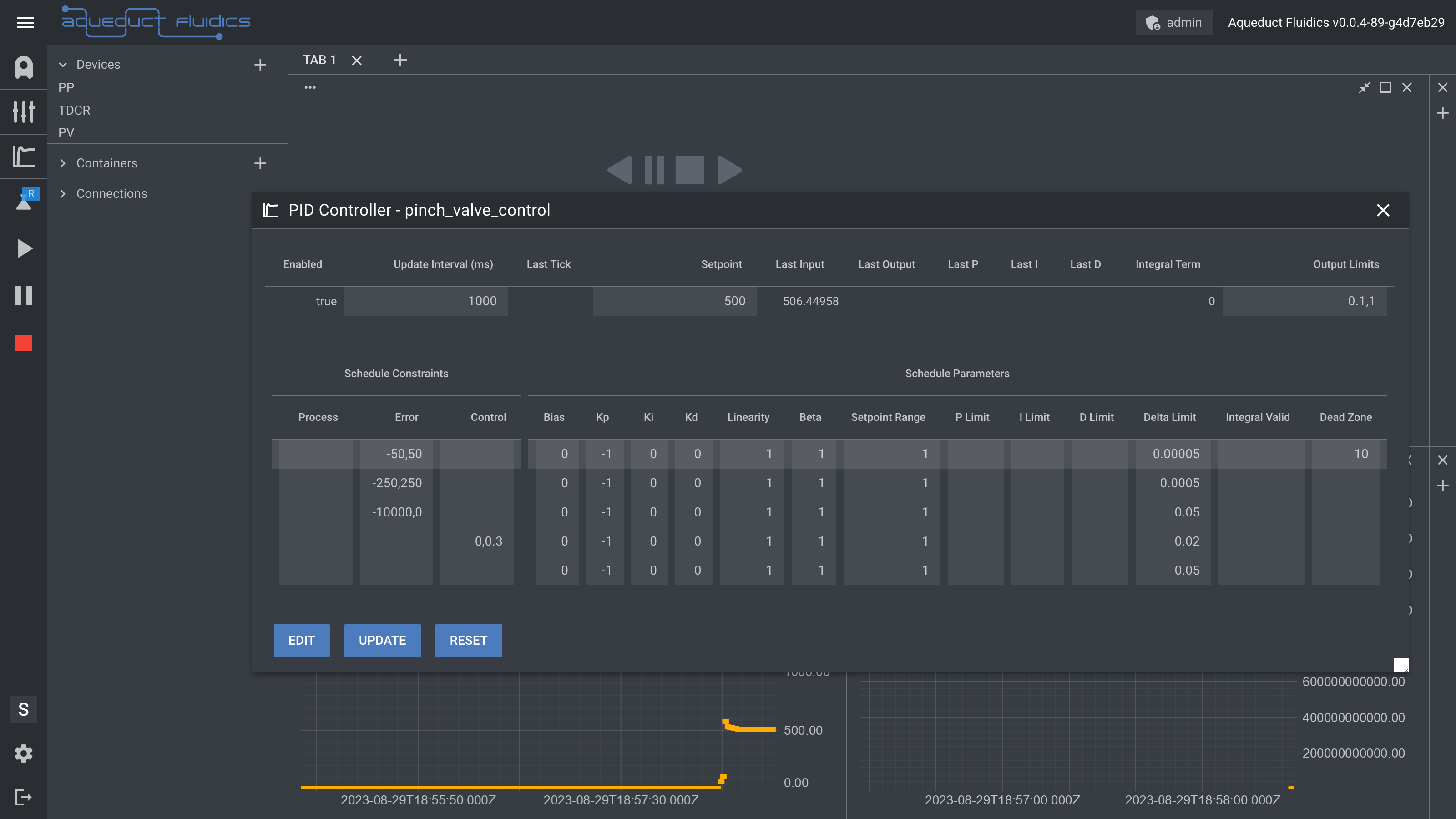

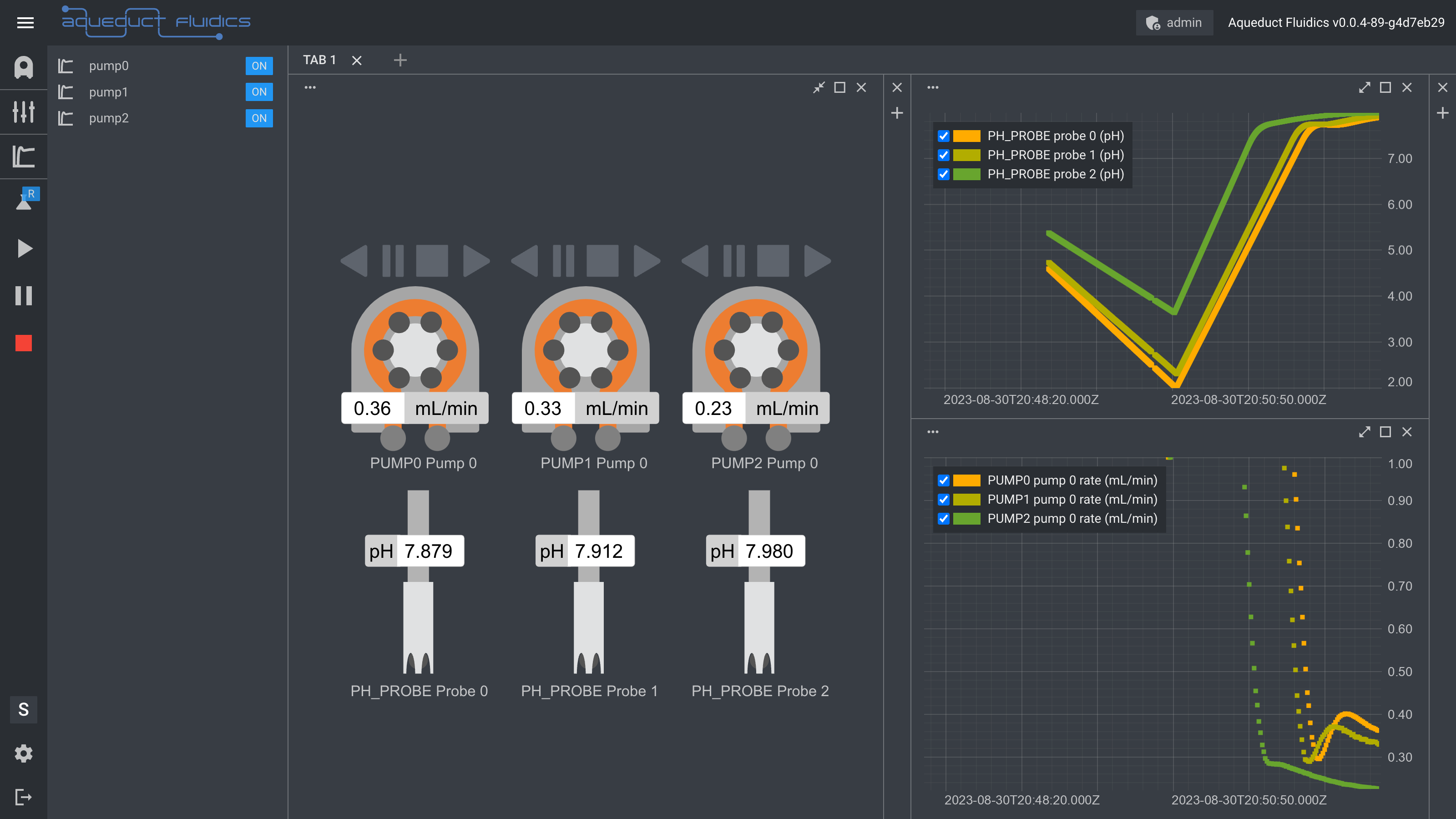

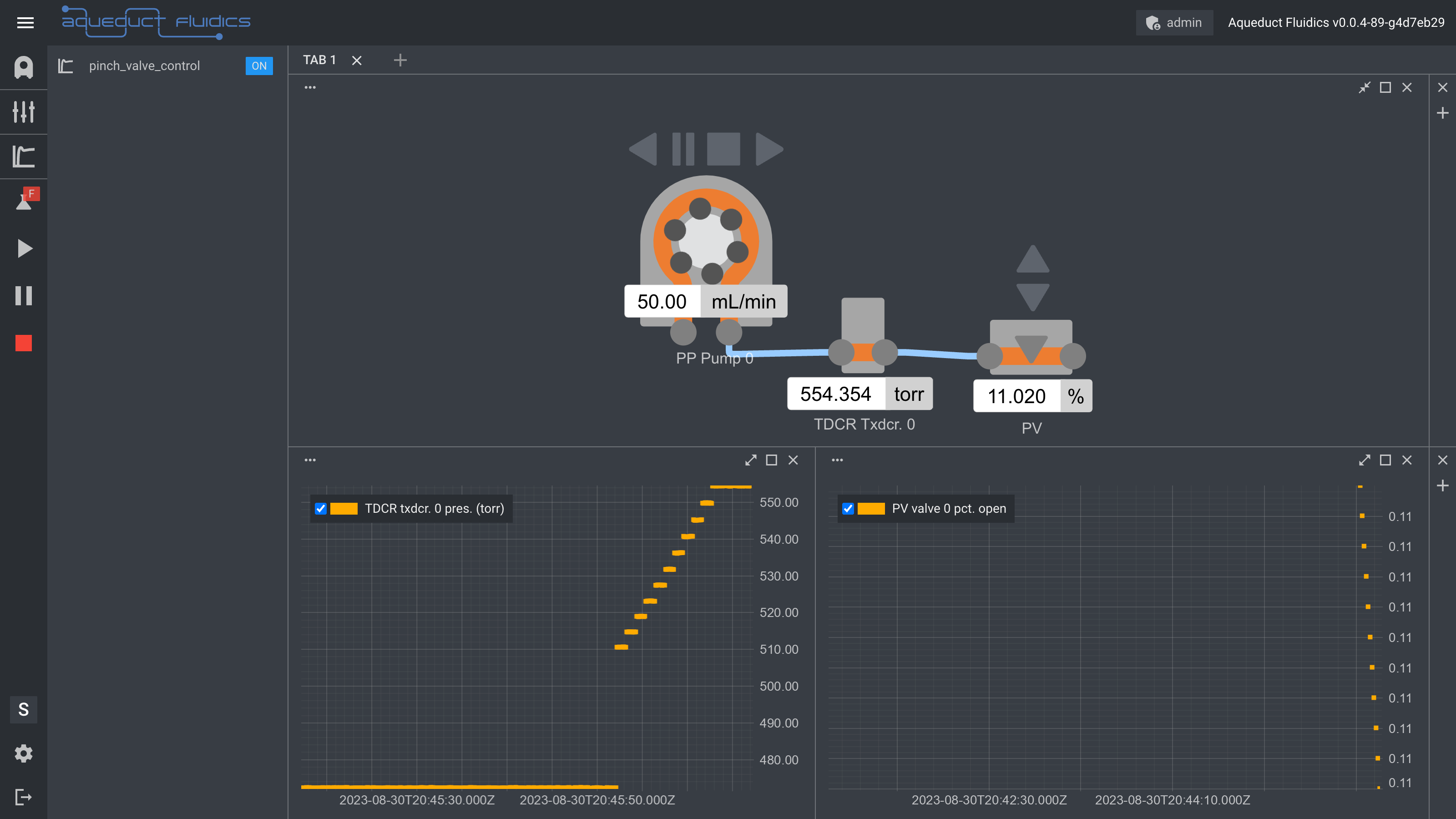

Built-In System and Data Visualization

The Aqueduct interface provides an intuitive and flexible environment for controlling and visualizing the status of your hardware. It features an icon-based representation of the hardware, live plotting and graphing utilities, and programmable user interactions. The interface can be customized to suit individual preferences and application requirements.

-

Simulation of Processes without Hardware

The Aqueduct platform offers simulation-only representations of each type of hardware component. These emulated devices faithfully mimic the behavior of real hardware, allowing users to develop and test Recipes without the need for physical lab equipment. Additionally, users can simulate noise or time-dependency in signals to accurately model their processes and control algorithms.

-

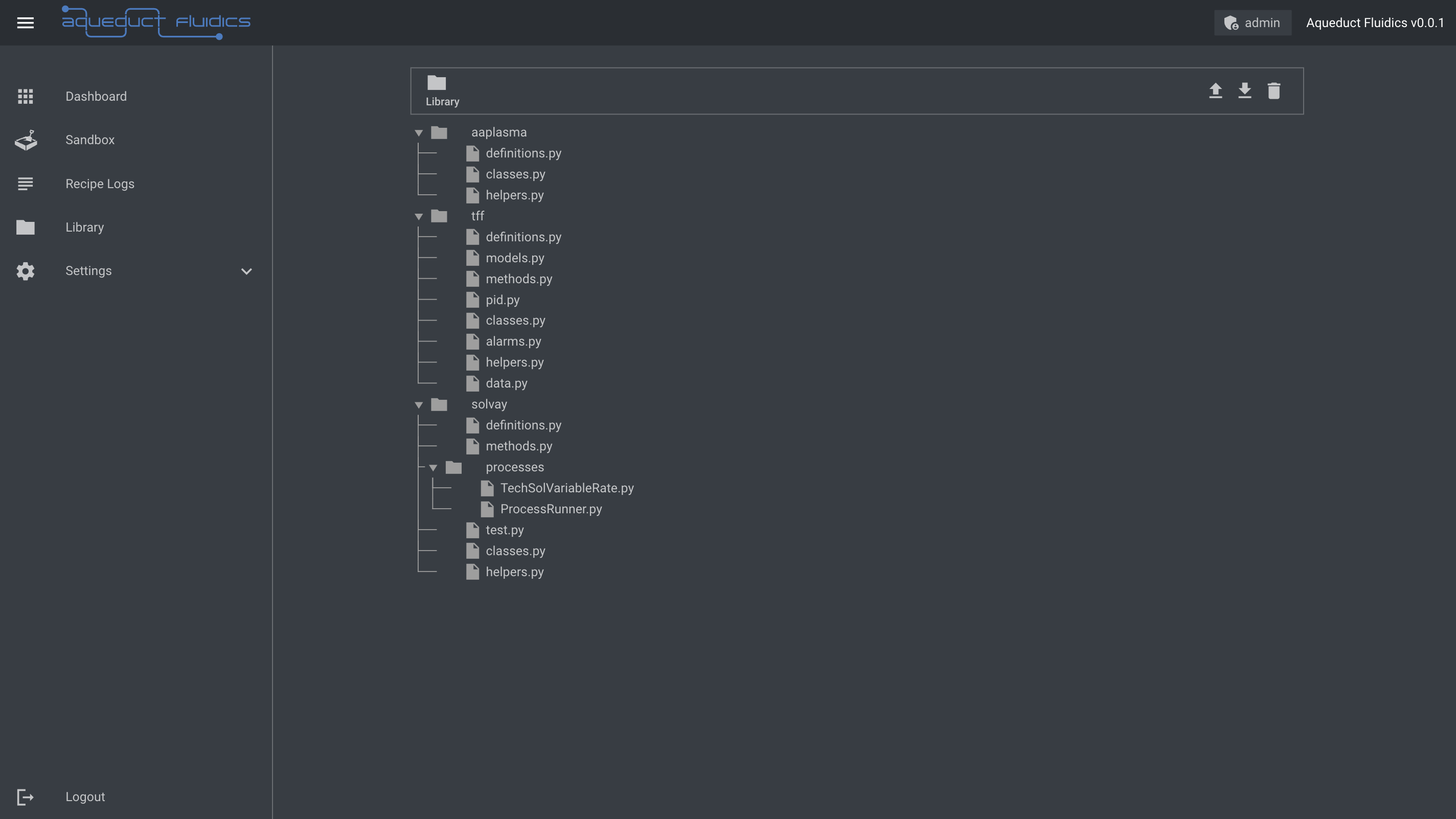

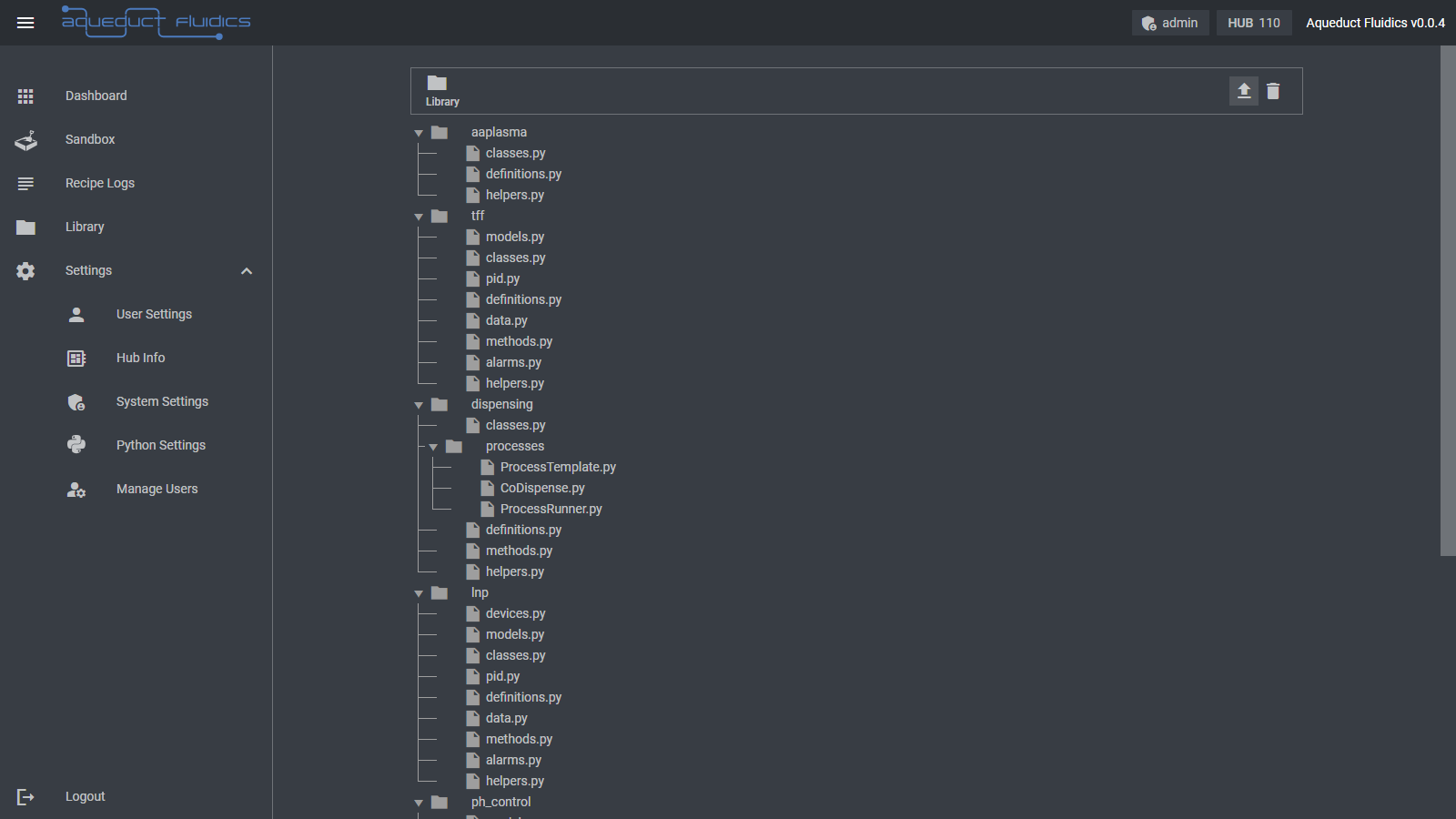

Ecosystem of Application Use Cases and Code Blocks for Rapid Development

Our platform provides an ecosystem of pre-existing, application-specific Libraries and Recipes that can be utilized off-the-shelf or customized to suit individual needs. Alternatively, users can leverage our collection of code snippets and templates to build their solutions from scratch, minimizing development time.

Tangential Flow Filtration (TFF) - also referred to as cross flow filtration - is a fast and effective technique for separating and purifying biomolecules.

In the TFF process, fluid flows tangentially along the surface of a filter membrane. Through the application of a pressure differential within the system, smaller constituents that can pass through the membrane's pore structure are directed into the filtrate, while larger constituents are retained and recirculated along the system's flow path.

TFF is utilized across diverse biological domains including immunology, protein chemistry, molecular biology, biochemistry, and microbiology. TFF is effective for concentrating and desalting sample solutions, fractionating large and small biomolecules, collecting cell suspensions, and clarifying fermentation broths and cell lysates.

Control is Paramount

Control is paramount in TFF. Precise manipulation of key parameters drives the efficiency and effectiveness of the process. Key control parameters include:

Transmembrane Pressure (TMP)

Transmembrane pressure -- the differential pressure across the filter membrane -- plays a pivotal role in process efficiency. By controlling the pressure differential across the membrane, the permeation of substances through the filter can be precisely managed, ensuring the desired separation and purification outcomes.

Crossflow Rate

In conjunction with the TMP, crossflow rate plays a significant part in determining process yield. By optimizing the crossflow rate, fouling and clogging risks are minimized, leading to consistent and reliable results.

Feed Concentration

In continuous diafiltration, salts or solvents (low molecular weight species) in the feed liquid are continuously removed by passes through the filter cartridge. As the unwanted species are pulled through the filter membrane, a replacement buffer (or water) solution is added to the feed container to keep the concentration constant.

Control over these parameters isn't just about achieving optimal results; it's about reproducibility and scalability. A well-controlled TFF process ensures that results obtained in the laboratory can be translated to larger-scale applications with confidence.

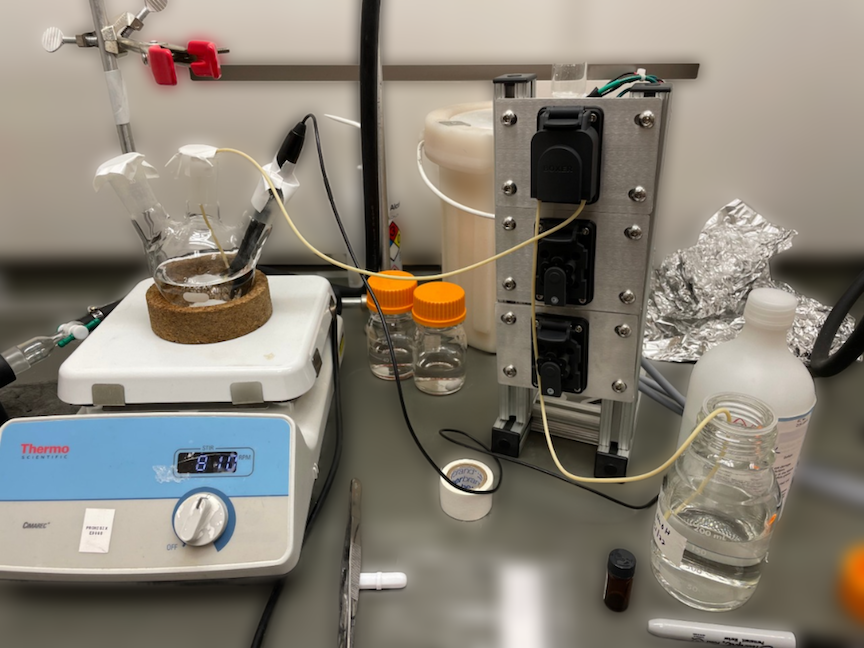

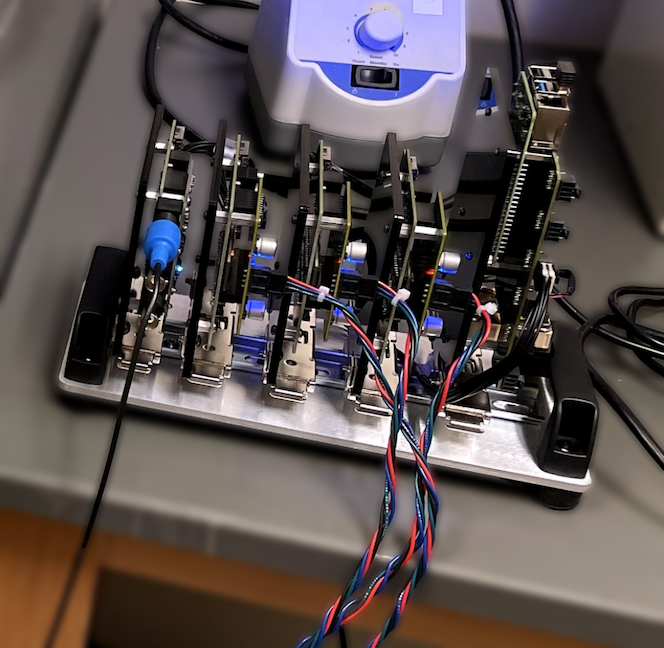

The Aqueduct Fluidics openTFF System

We're building the Aqueduct Fluidics openTFF system to be a comprehensive automation solution tailored for lab-scale TFF processes.

The system includes an embedded computer and a dedicated interface board, both enclosed in a sealed housing.

The interface board features three dedicated Mixed IO (MIO) interfaces designed to control laboratory pumps (see a list of compatible pumps here). A 4-20mA speed control output signal and a 4-20mA tachometer input signal enable low-latency speed control and real-time volume accumulation for accurate volume measurement and precise finite dispenses. Two isolated digital outputs enable the manipulation of run and direction toggles while an isolated digital input provides monitoring of pump status (running or stopped).

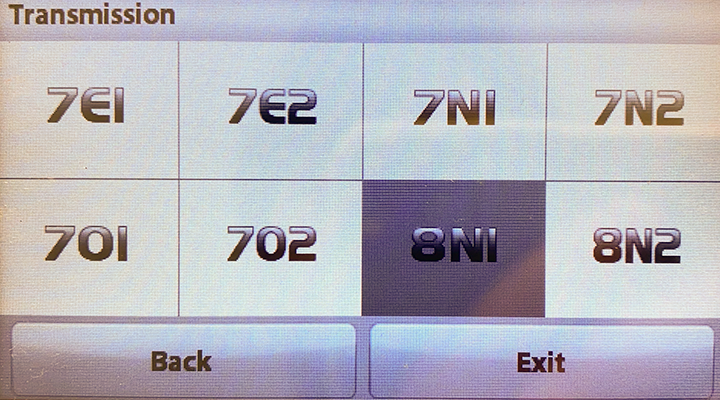

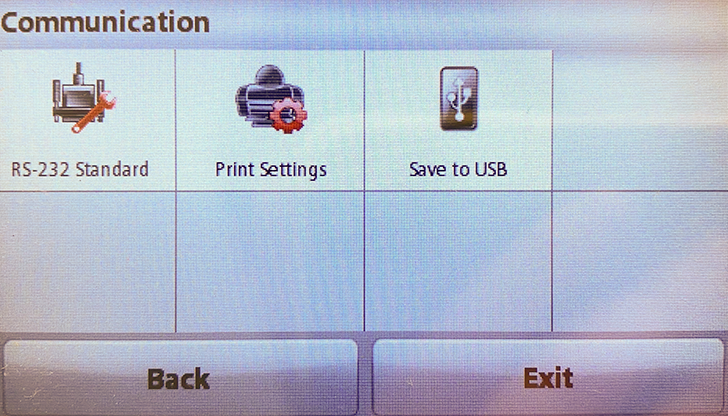

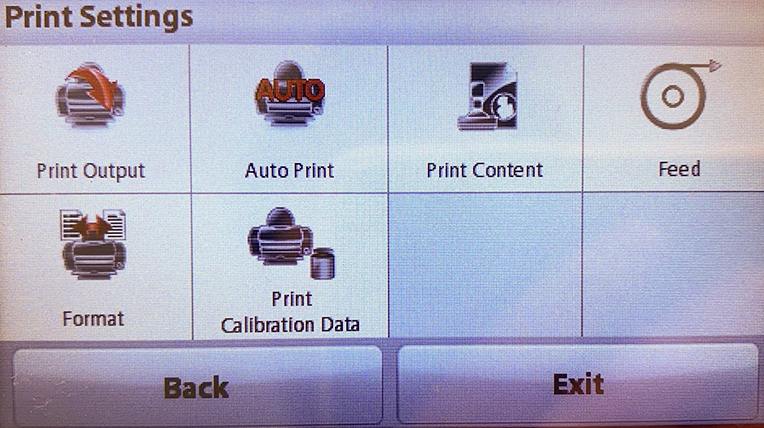

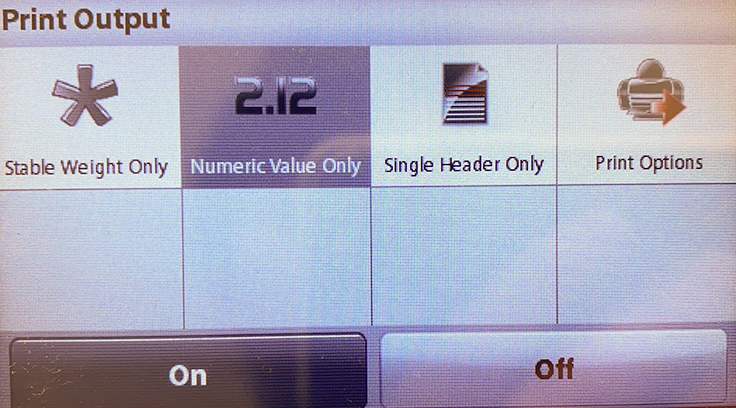

Four serial communication ports facilitate communication and control of a range of peripherals such as balances, pressure transducers, and recirculating baths, enhancing the system's flexibility and applicability across various setups. By simply configuring the application to recognize the peripheral you have connected, the Aqueduct drivers take care of reading data into the application.

The system includes an Aqueduct Comm bus. This 4-wire, full-duplex RS485 communication interface is exclusively dedicated to interfacing with the Aqueduct pinch valve or other additional nodes, thereby offering the potential for system expansion and integration with other components.

Built for Flexibility

The system's modular design allows you to tailor your setup according to your specific process needs. The system allows you to integrate a variety of components, including balances, pH probes, conductivity probes, pressure transducers, and recirculating baths.

Scalability and Adaptability

The openTFF system is designed to grow with your requirements. As your process evolves, you can expand the system by adding new components or functionalities. This scalability ensures that your investment remains relevant and valuable over time, accommodating changing demands and advancing technologies.

Integration with Existing Setup

The openTFF system may be compatible with your existing equipment. Whether you already have certain pumps, sensors, or instruments in place, the system's adaptability enables it to seamlessly integrate with your current laboratory infrastructure.

Full Utilization of Aqueduct Capabilities

By leveraging the capabilities of the Aqueduct platform, the openTFF system provides advanced features that enhance your TFF processes:

-

Simulation Mode: Test and refine your process logic in a simulated environment, minimizing risks and optimizing parameters before implementing them in the actual setup.

-

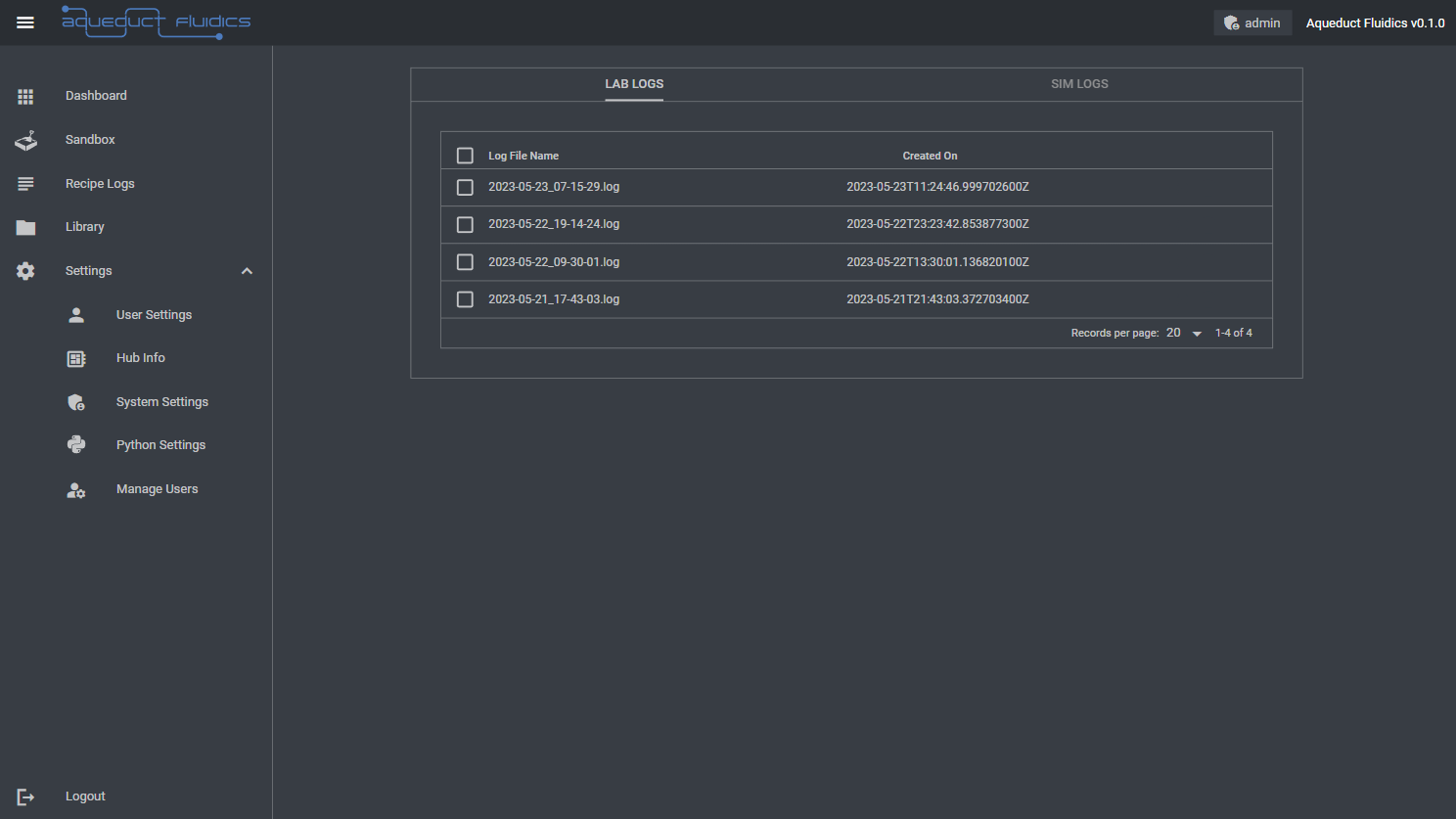

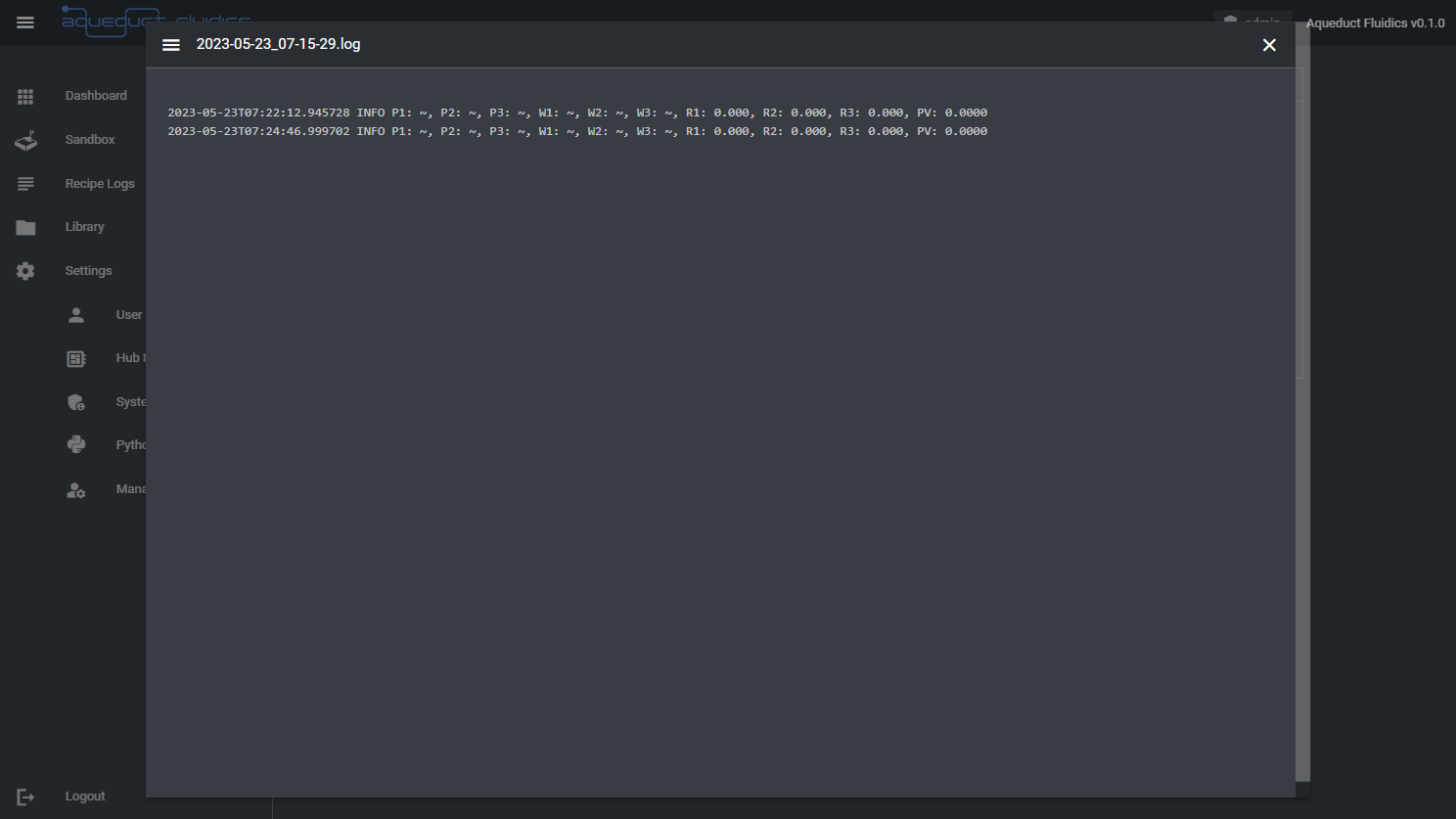

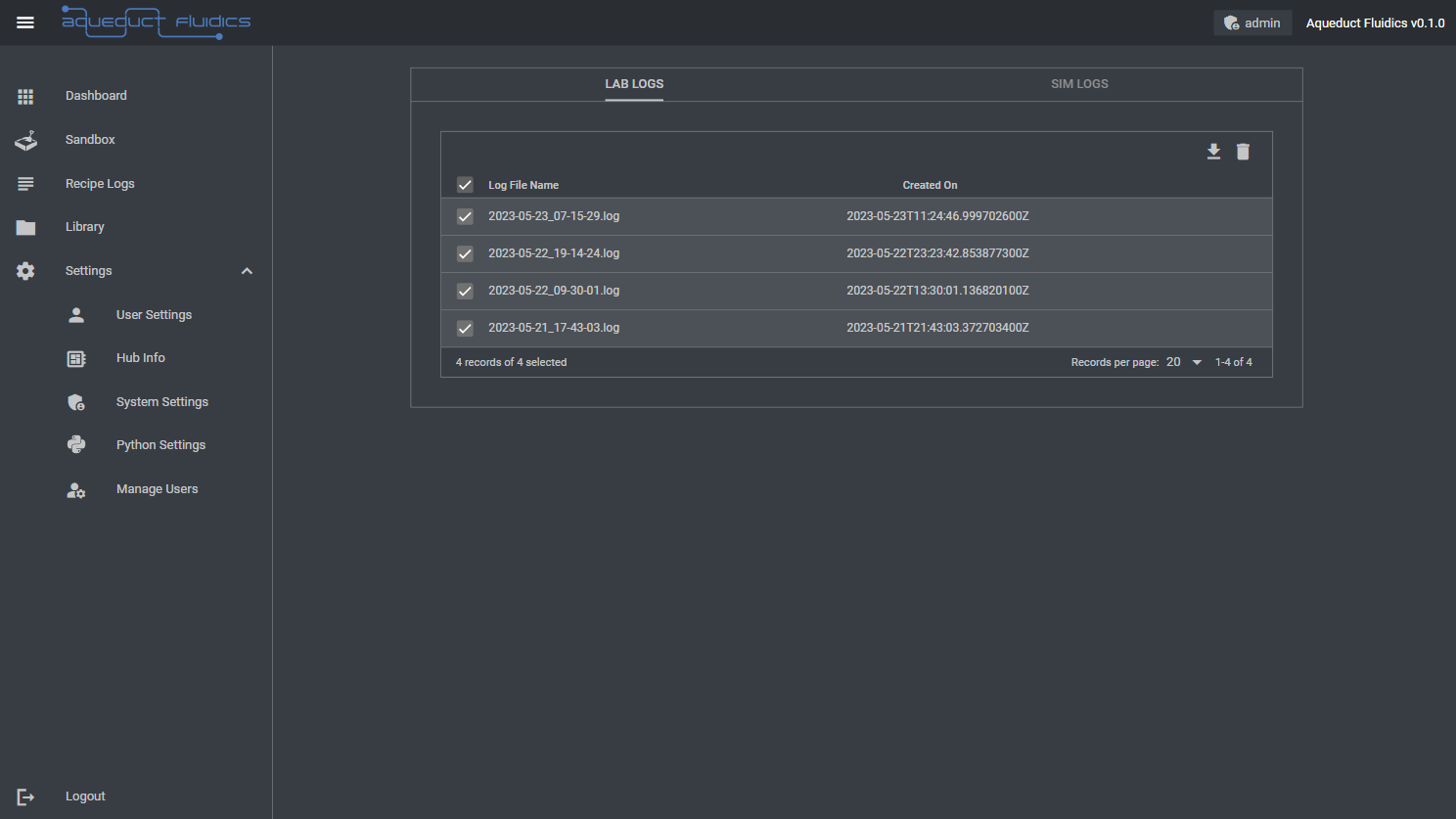

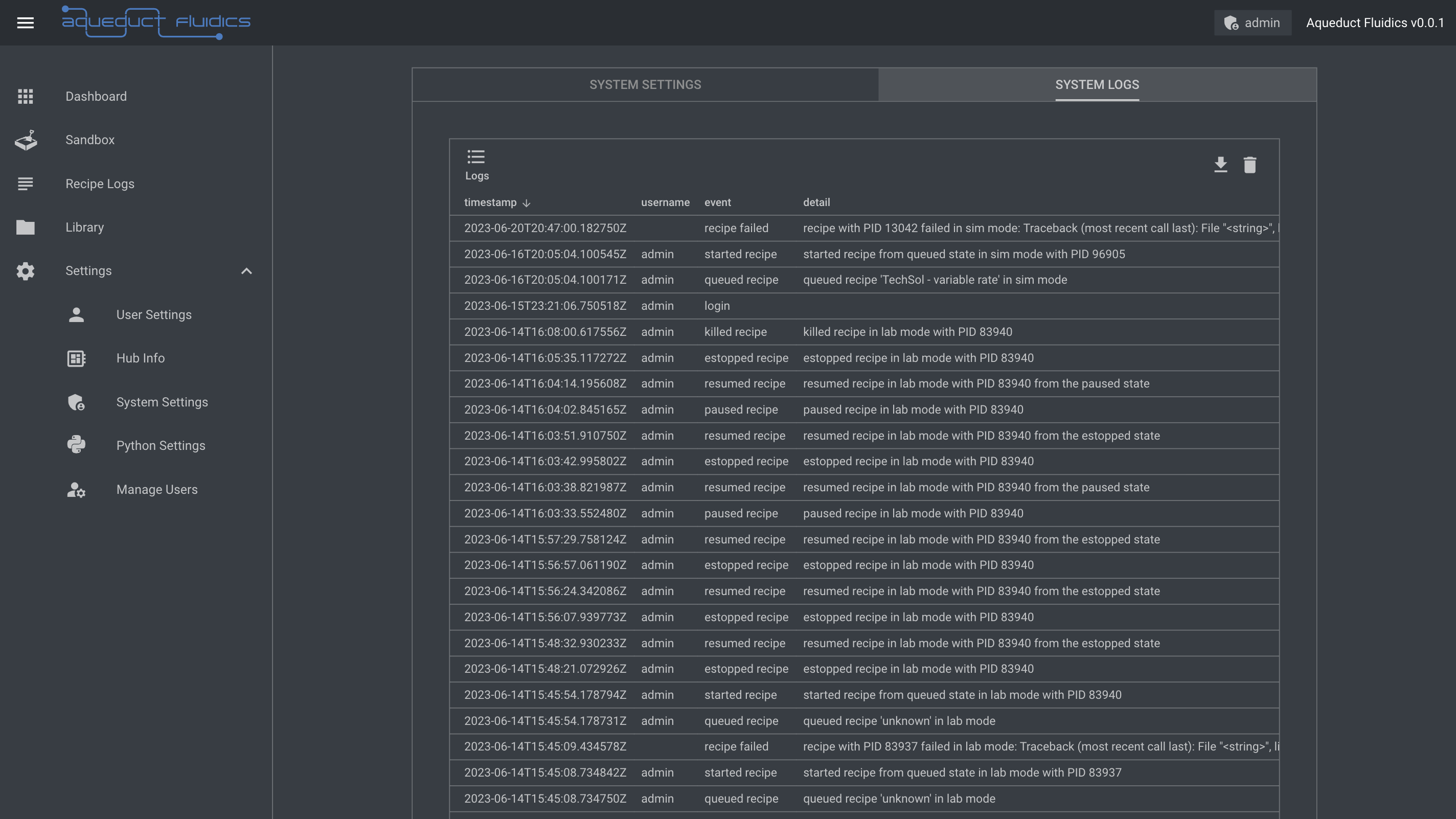

Event Logging: Capture real-time data and events for comprehensive process documentation, analysis, and troubleshooting. This valuable information supports quality control and process improvement efforts.

-

Third-Party Integration: Integrate third-party databases or APIs into the Aqueduct platform, enabling enhanced data management. This integration expands the system's potential applications and connectivity.

Streamlined Process Development

The openTFF system accelerates process development by offering a user-friendly interface for configuring and controlling various components. The ability to fine-tune parameters and visualize their impact allows for rapid optimization and quicker process deployment.

Contact Us

If you're interested in learning more about the system or have specific requests for peripherals you would like to see added, contact us at info@aqueductfluidics.com.

Interface Circuit Board

The openTFF Interface board includes three specialized Mixed I/O (MIO) interfaces tailored for pump control, four configurable serial communication ports, and an Aqueduct CommBus interface. These interfaces ensure precise control, data communication, and expansion possibilities.

Three Dedicated Mixed I/O Ports for Controlling Pumps

The openTFF system is equipped with three specialized Mixed I/O (MIO) interfaces designed to control pumps (peristaltic, piston, and diaphragm) commonly used in a TFF setup. These MIO interfaces feature:

-

4-20 mA Speed Control Channel: This channel transmits a 4-20 mA signal used to control the speed of a pump, ensuring accurate and precise fluid flow rates.

-

4-20 mA Tachometer Input Channel: The tachometer input channel is responsible for receiving a 4-20 mA signal from the pump's tachometer. The tachometer measures the rotational speed (or a proxy for flow rate, depending on the model) of a pump. The interface not only monitors the pump's speed but also accumulates real-time data to calculate the total volume of fluid displaced, enabling finite dispense operation.

-

Digital Inputs and Outputs Channels: Two digital output channels and a digital input channel are used to control the run and direction toggles of the connected pump and monitor the pump's status.

8 pin M12 A-code plug, male pins

|

|

|

Four Configurable Serial Interfaces

In addition to the three specialized MIO interfaces, the openTFF system includes four serial communication ports. In conjunction with the Aqueduct software, these ports can be configured to interface with various peripherals commonly used in TFF setups. Among these ports, two can be configured for half-duplex RS485 communication, enhancing compatibility with a wide range of industrial devices.

3 pin M8 A-code plug, male pins

|

|

|

Aqueduct CommBus Interface

8 pin M12 A-code receptacle, female pins

|

|

|

Supported Hardware (Preliminary)

Balances

| Brand | Supported Models | Interface Type | External Node Required | Connections |

|---|---|---|---|---|

| Mettler Toledo | XP/XS Series, XPE/XSE Series | RS232 | no | (coming soon) |

| Sartorius | Cubis, Quintix | RS232 | no | (coming soon) |

| Ohaus | Explorer®, Adventurer®, Scout® Series | RS232 | no | link |

Pressure Transducers

| Brand | Supported Models | Interface Type | External Node Required | Connections |

|---|---|---|---|---|

| Parker SciLog® | SciPres® | RS232 | no | link |

| Pendotech | PressureMAT® | RS232 | no | (coming soon) |

pH Probes

| Brand | Supported Models | Interface Type | External Node Required | Connections |

|---|---|---|---|---|

| Aqueduct pH ADC Node | most standard pH electrodes (supports 3) | BNC | yes | (coming soon) |

| Thermo Fisher | Orion Star A Series | RS232 | no | (coming soon) |

Conductivity Probes

| Brand | Supported Models | Interface Type | Inline/Immersion | External Node Required | Connections |

|---|---|---|---|---|---|

| Parker SciLog® | SciCon® | RS232 | inline | no | (coming soon) |

| Thermo Fisher | Orion Star A Series | RS232 | no | (coming soon) |

Pinch Valves

| Brand | Supported Models | Interface Type | External Node Required | Connections |

|---|---|---|---|---|

| Aqueduct | Pinch Valve | Aqueduct CommBus | yes | link |

MIO Pumps

MIO Port - Masterflex L/S® DB25 Connections

|

|

|

| Aqueduct MIO Pin | Signal | Masterflex L/S® Female Receptacle DB25 Pin |

|---|---|---|

| 1 | Aux Ground | 13 |

| 2 | Aux +24V | 25 |

| 3 | 4-20 mA RX, Tachometer | 4 |

| 4 | 4-20 mA TX, Speed Control | 2 |

| 5 | Running Digital In | 6 |

| 6 | Run Digital Out | 15 |

| 7 | Direction Digital Out | 16 |

| 8 | Aux Ground | 3 |

Recommended Cable Assembly Bill of Materials

| Manufacturer | Part Description | Part Number | Quantity |

|---|---|---|---|

| Phoenix Contact | Sensor/actuator cable, 8-position | 1406105 | 1 |

| Cinch Connectivity | 25 Position Two Piece Backshell Connector | 40-9725HMG | 1 |

| TE Connectivity AMP Connectors | 25 Position D-Sub Plug, Male Pins | 5-747912-2 | 1 |

| Conductor Number | Conductor Color | D-Sub Plug DB25 Pin |

|---|---|---|

| 1 | White (⚪) | 13 |

| 2 | Brown (🟤) | 25 |

| 3 | Green (🟢) | 4 |

| 4 | Yellow (🟡) | 2 |

| 5 | Grey (⚪) | 6 |

| 6 | Pink (🟣) | 15 |

| 7 | Blue (🔵) | 16 |

| 8 | Red (🔴) | 3 |

Further information in the Masterflex L/S® manual here.

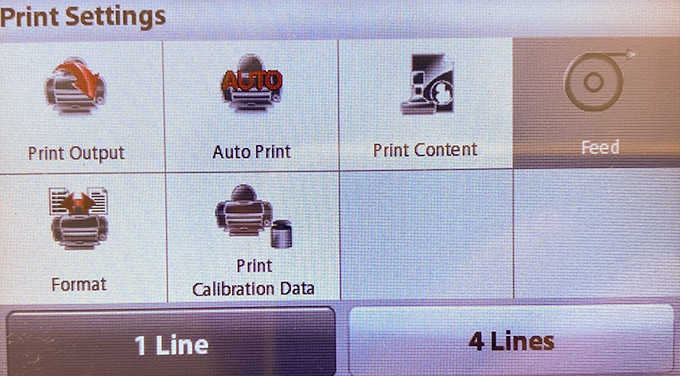

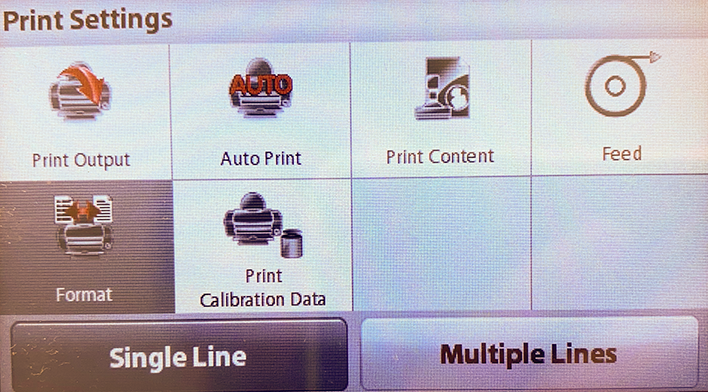

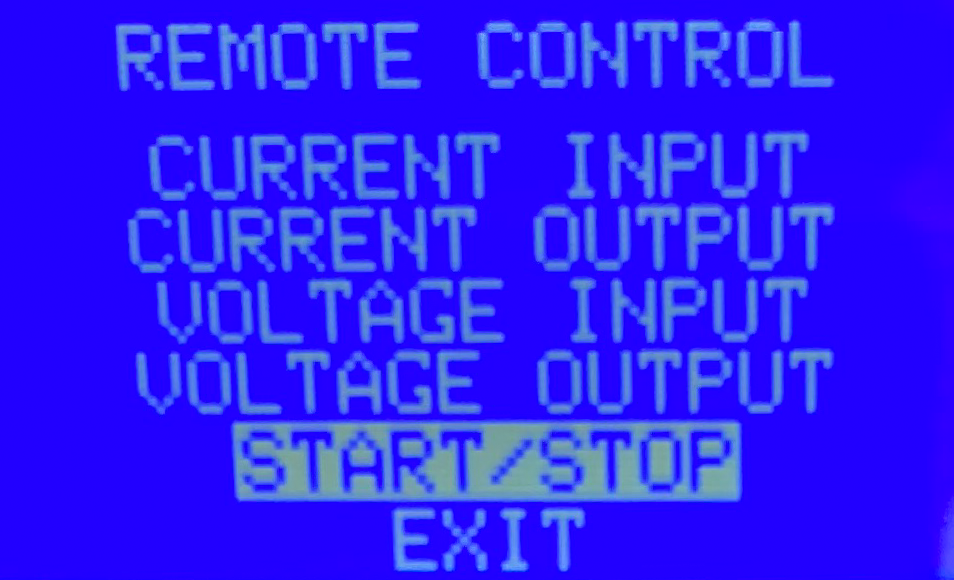

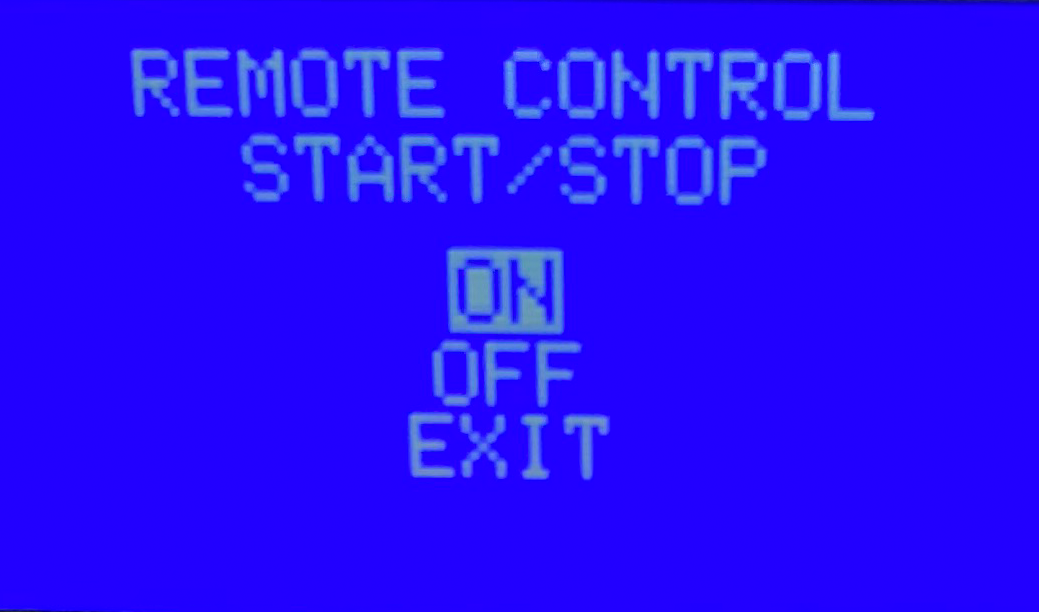

See instructions for configuring the pump and calibrating the speed control and tachometer output signals here.

MIO Port - Watson Marlow DB25 Connections

|

|

|

| Aqueduct MIO Pin | Signal | Watson Marlow 530U, 630U Upper Male Plug DB25 Pin |

|---|---|---|

| 1 | Aux Ground | 16 |

| 2 | Aux +24V | 20 |

| 5 | Running Digital In | 10 |

|

|

|

| Aqueduct MIO Pin | Signal | Watson Marlow 530U, 630U Lower Female Receptacle DB25 Pin |

|---|---|---|

| 3 | 4-20 mA RX, Tachometer | 12 |

| 4 | 4-20 mA TX, Speed Control | 4 |

| 6 | Run Digital Out | 7 |

| 7 | Direction Digital Out | 6 |

| 8 | Aux Ground | 14 |

Further information in the Watson Marlow 530U manual here.

Balances

Serial Port - Ohaus RS232 DB9 Connections

|

|

|

| Aqueduct Comm Pin | Signal | Ohaus RS232 Female Receptacle DB9 Pin |

|---|---|---|

| 1 | Ground | 5 |

| 3 | Rs485 A/Rs232 Tx | 3 |

| 4 | Rs485 B/Rs232 Rx | 2 |

Recommended Cable Assembly Bill of Materials

| Manufacturer | Part Description | Part Number | Quantity |

|---|---|---|---|

| Phoenix Contact | Sensor/actuator cable, 3-position | 1406318 | 1 |

| Cinch Connectivity | 9 Position Two Piece Backshell Connector | 40-9709HMG | 1 |

| TE Connectivity AMP Connectors | 9 Position D-Sub Plug, Male Pins | 5-747904-2 | 1 |

| Conductor Number | Conductor Color | D-Sub Plug DB9 Pin |

|---|---|---|

| 1 | Brown (🟤) | 5 |

| 3 | Blue (🔵) | 3 |

| 4 | Black (⚫) | 2 |

Further information in the Ohaus Scout RS232 interface manual here.

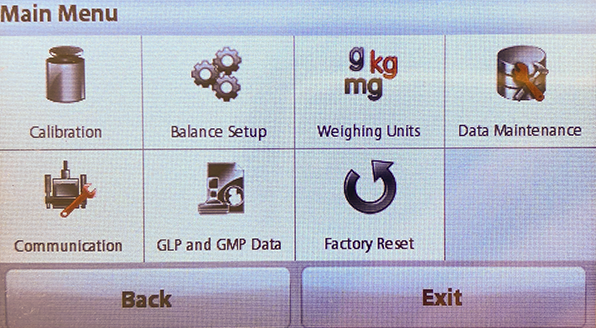

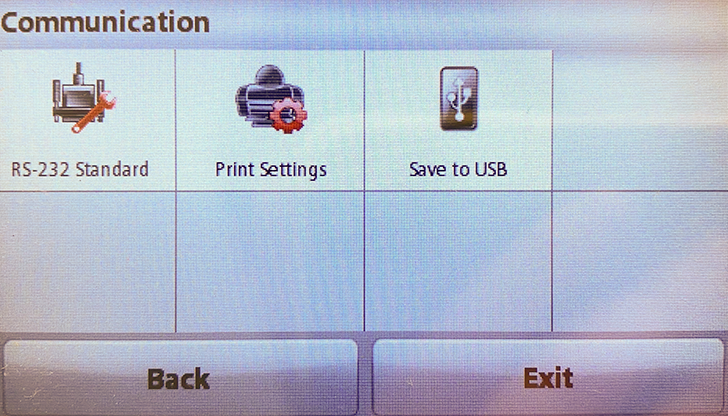

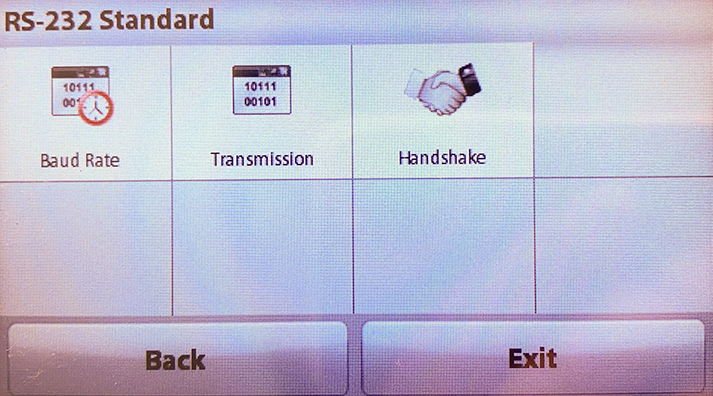

See instructions for configuring the balance here.

Pressure Transducers

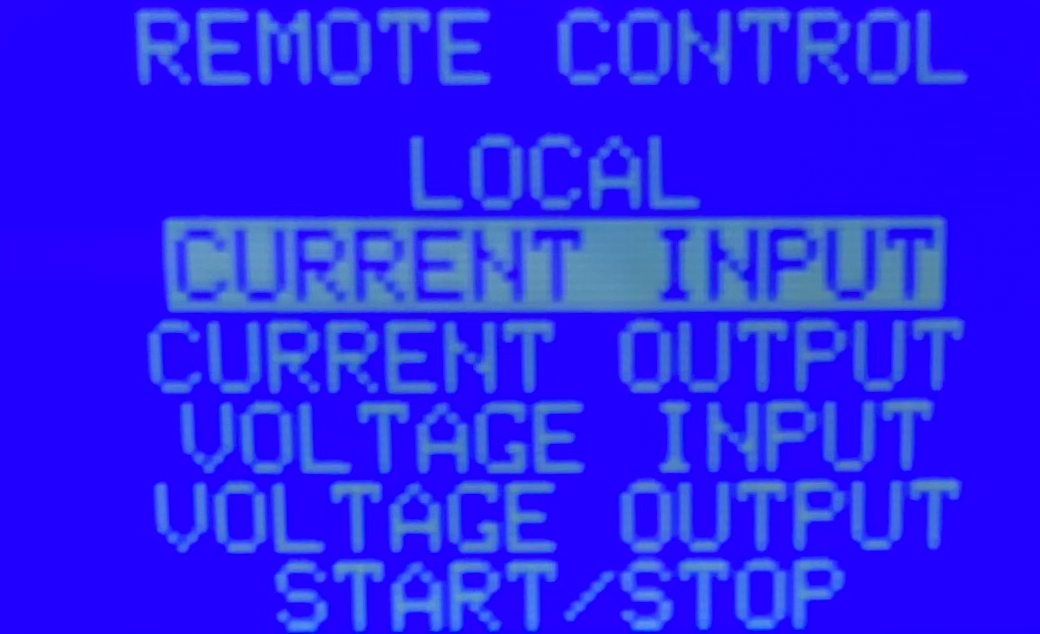

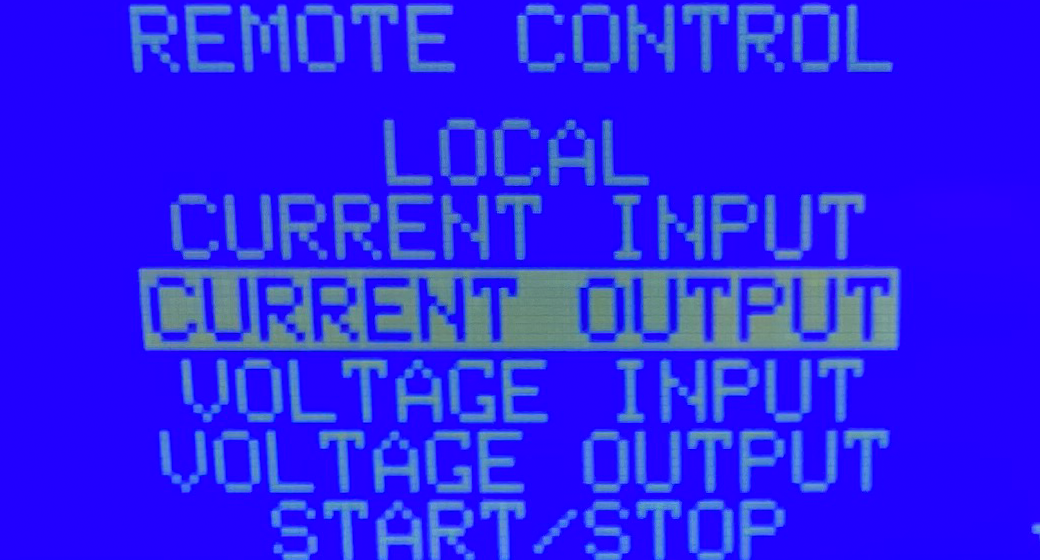

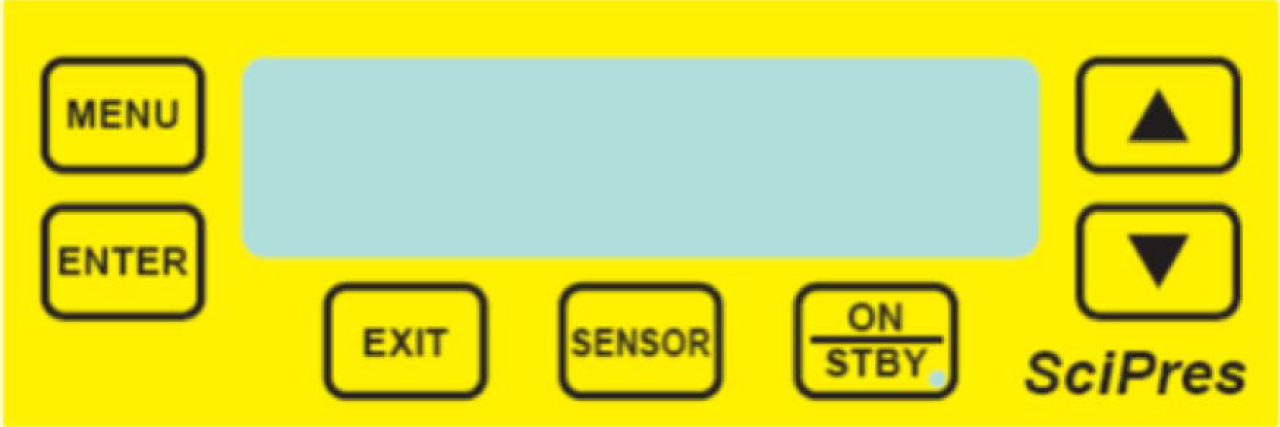

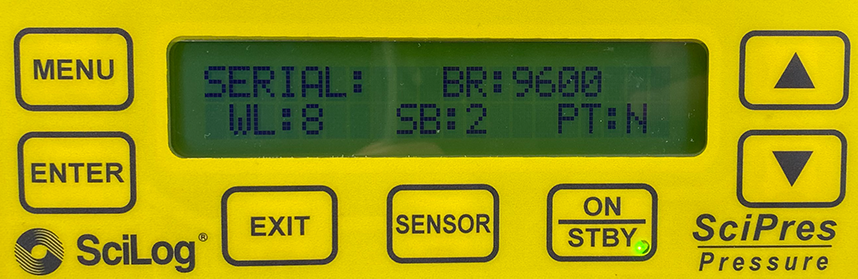

Serial Port - Parker SciLog® SciPres® DB9 Connections

|

|

|

| Aqueduct Comm Pin | Signal | SciLog® SciPres® RS232 Female Receptacle DB9 Pin |

|---|---|---|

| 1 | Ground | 5 |

| 3 | Rs485 A/Rs232 Tx | 3 |

| 4 | Rs485 B/Rs232 Rx | 2 |

Recommended Cable Assembly Bill of Materials

| Manufacturer | Part Description | Part Number | Quantity |

|---|---|---|---|

| Phoenix Contact | Sensor/actuator cable, 3-position | 1406318 | 1 |

| Cinch Connectivity | 9 Position Two Piece Backshell Connector | 40-9709HMG | 1 |

| TE Connectivity AMP Connectors | 9 Position D-Sub Plug, Male Pins | 5-747904-2 | 1 |

| Conductor Number | Conductor Color | D-Sub Plug DB9 Pin |

|---|---|---|

| 1 | Brown (🟤) | 5 |

| 3 | Blue (🔵) | 3 |

| 4 | Black (⚫) | 2 |

Note: Connect to the Female DB9 port labelled "Printer/PC".

Further information in the Parker SciLog® SciPres® manual here.

See instructions for configuring the balance here.

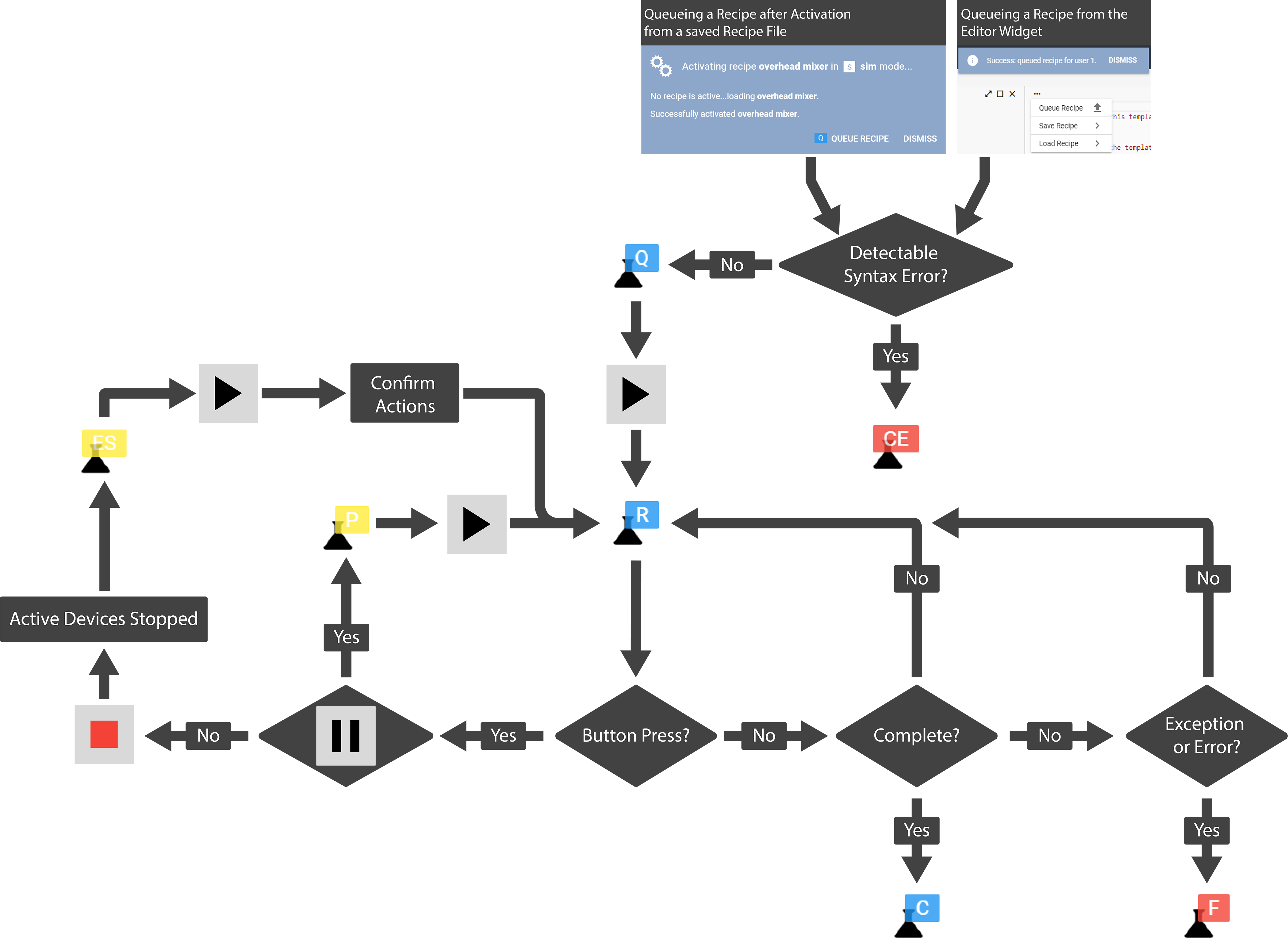

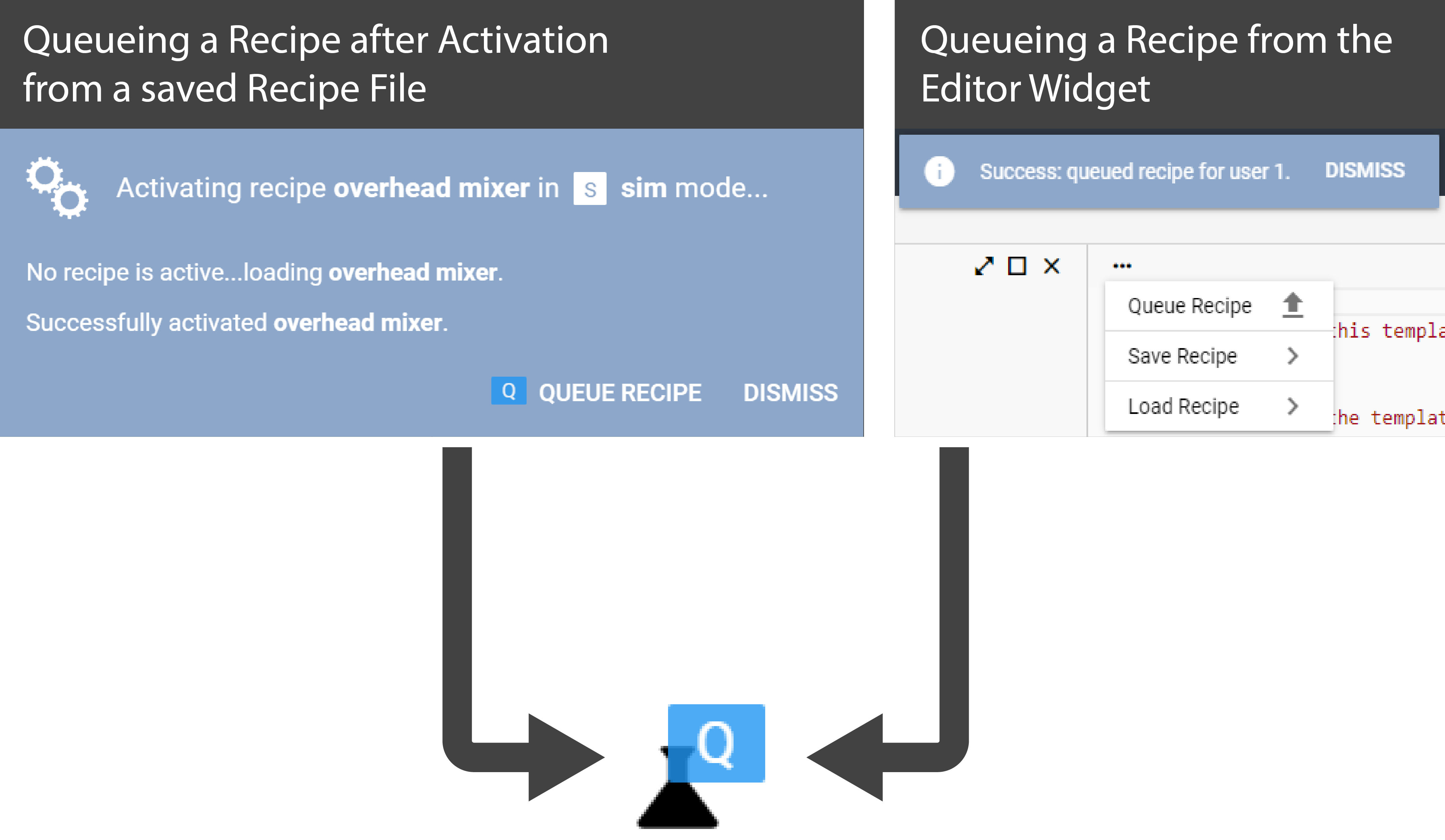

Simulating a TFF Process Using the Aqueduct Application

The Aqueduct application provides simulation capabilities that allow for the modeling of a TFF process. This guide outlines how to model the process using mathematical equations and Python code. It covers calculations for retentate, feed, and permeate pressures, as well as rates-of-change for balances that measure buffer, feed, and permeate product volumes.

The approach outlined in this guide is not limited to TFF systems; it can be readily adapted for other in-line and batch bioprocess applications.

- Process Variables

- Calculating Pinch Valve \( \text{Cv} \)

- Calculating Retentate Pressure

- Calculating Feed Pressure

- Calculating Permeate Pressure

- Calculating Balance Rates-of-Change

- Appendix

Independent Process Variables

The model takes the following independent variables as input parameters:

- Feed Pump Rate - Flow rate of the feed pump (e.g., mL/min).

- Buffer Pump Rate - Flow rate of the buffer pump (e.g., mL/min).

- Permeate Pump Rate - Flow rate of the permeate pump (e.g., mL/min).

- Pinch Valve Position - Position of the pinch valve, converted into a Valve Flow Coefficient (Cv) value.

The independent process variables are set by user interactions (either through the UI or a an Aqueduct Recipe).

Dependent Variables

Using the independent process variables, the simulation calculates the following dependent variables:

- Feed Pressure - Pressure at the feed side of the filter.

- Retentate Pressure - Pressure on the retentate side of the filter.

- Permeate Pressure - Pressure on the permeate side of the filter.

- Weight on Buffer Balance - Weight rate-of-change on the buffer balance.

- Weight on feed Balance - Weight rate-of-change on the feed balance.

- Weight on Permeate Balance - Weight rate-of-change on the permeate balance.

graph TD A[Start] --> B[Calculate Pinch Valve Cv]; B --> C[Calculate Retentate Pressure<br>using Pinch Valve Cv and Feed Rate]; C --> D[Calculate Feed Pressure<br>using Permeate Pressure, Filter Cv, and Feed Rate]; D --> E[Calculate Permeate Pressure<br>using Feed and Retentate Pressure<br>and Permeate Flux]; E --> F[Calculate Mass Accumulation<br>on Feed, Buffer, and Permeate<br>Balances using Feed Rate,<br>Permeate Flux, and Buffer Pump Rate]; F --> G[End]; click B "#calculating-pinch-valve-textcv" _blank click C "#calculating-retentate-pressure" _blank click D "#calculating-feed-pressure" _blank click E "#calculating-permeate-pressure" _blank click F "#calculate-balance-rates-of-change" _blank

Calculating Pinch Valve \(\text{Cv}\)

We start the \(\text{Cv}\) calculation by estimating the percentage of occluded area in the cross-section of a tube based on its change in height (\( \Delta h \)).

The underlying mathematics are derived from this paper. The occlusion value scales between 0 and 1, where 1 indicates maximum occlusion (tube completely pinched), and 0 indicates no occlusion (tube retains original shape).

@staticmethod

def occluded_area_pct(delta_h: float) -> float:

"""

Calculate the percentage change in cross-sectional area of a

tube when it's squeezed, based on the change in height.

See: https://www.hindawi.com/journals/mpe/2015/547492/

Parameters:

delta_h (float): The change in height due to the squeeze as a

fraction of the original height (ranging from 0 to 1).

Returns:

float: The percentage change in the new cross-sectional area, scaled between 0 and 1.

1 indicates maximum occlusion (tube completely flat),

0 indicates no occlusion (tube retains original shape).

"""

x = max(.5 - delta_h, 0)

oc = math.pi * x * (math.sqrt(-20 * x**2 + 12 * x + 3) / 6 - (2 * x / 3) + 0.5)

oc = min(-1 * (oc-0.7853981633974483), 1)

return oc

The occluded area vs. \( \Delta h \) relationship is illustrated in the following plot:

After calculating the percentage of occluded area, we scale the original tube cross sectional area using the inner diameter in mm to \(\text{Cv}\) value using the functions:

@staticmethod

def cv_from_area_mm(area_mm: float) -> float:

# Convert the area from mm^2 to m^2

area_m = area_mm * 1e-6

# Calculate the diameter from the area

diameter_m = math.sqrt((4 * area_m) / math.pi)

# Calculate Cv using the given formula

Cv = (((diameter_m) ** 2) * 0.61) * 46250.9

return Cv

@staticmethod

def calc_pv_cv(position: float) -> float:

"""

Calculate the Cv of the pinch valve.

:param PV: Pinch valve position.

:type PV: float

:return: Cv of the pinch valve.

:rtype: float

"""

response_zone = 0.35

if position < response_zone:

area = (math.pi * (5 / 2)**2) * \

(1 - PressureModel.occluded_area_pct((response_zone - position)/response_zone))

return PressureModel.cv_from_area_mm(area_mm=area)

else:

return 100

Pinch Valve \(\text{Cv}\) Calculation

Next, we calculate the \(\text{Cv}\) value using the following steps:

-

Check Valve Position: If the valve's open position is below the

response_zonethreshold (0.35), we proceed to calculate the Cv by adjusting the cross-sectional area of the tube. This simulates the large range of the pinch valve position that does not have any affect on the tubing restriction area and will help us to develop control algorithms later. -

Calculate Occluded Area: We use the

occluded_area_pctmethod to find the percentage of the tube's area that is occluded or squeezed due to the valve's position. -

Scale Original Tube Area: The original cross-sectional area of the tube (calculated using the tube's inner diameter of 5 mm) is then scaled by

(1 - occluded_area_pct)to find the actual cross-sectional area when the valve is at the given position. -

Calculate Cv: With the actual area in hand, we proceed to calculate the Cv value using the

cv_from_area_mmmethod.

The following plot illustrates the relationship between \(\text{Cv}\) and the pinch valve position (in percent open, from 0 to 1).

Calculating Retentate Pressure

After we've calculated the flow coefficent \(\text{Cv}\) of the pinch valve based on its position, we can calculate the retentate pressure.

-

Obtain Feed Pump Rate: We use the (independent) feed pump rate process variable to set the mass flow through the restriction, \(Q\).

-

Apply Flow-Pinch Valve Relationship: The pressure drop across a restriction is related to the flow rate \(Q\) and the \(\text{Cv}\) of the restriction by the equation:

\[ \Delta P_{\text{psi}} = \left( \frac{Q}{0.865 \times \text{Cv}} \right)^2 \times 14.5038 \]

Here, \(\Delta P\) is the pressure drop across the valve, \(Q\) is the mass flow rate in \(\frac{m^3}{hr}\), and \(\text{Cv}\) is the flow coefficient of the restriction.

In Python, the calc_delta_p_psi method is used to perform the calculation:

@staticmethod

def calc_delta_p_psi(mass_flow_rate_ml_min: float, cv: float) -> float:

"""

Calculate the pressure drop between through a restriction

using the metric equivalent flow factor (Kv) equation:

Kv = Q * sqrt(SG / ΔP)

Where:

Kv : Flow factor (m^3/h)

Q : Flowrate (m^3/h)

SG : Specific gravity of the fluid (for water = 1)

ΔP : Differential pressure across the device (bar)

Kv can be calculated from Cv (Flow Coefficient) using the equation:

Kv = 0.865 * Cv

:param mass_flow_rate_ml_min: Flowrate.

:type mass_flow_rate_ml_min: float

:param cv: Flow Coefficient.

:type cv: float

:return: Pressure drop (psi).

:rtype: float

"""

try:

kv = 0.865 * cv

# Convert mL/min to m^3/h

delta_p_bar = 1 / (kv / (mass_flow_rate_ml_min / 60.0)) ** 2

delta_p_psi = delta_p_bar * 14.5038 # Convert bar to psi

return delta_p_psi

except ZeroDivisionError:

return 0

- Calculate Retentate Pressure: Now that we have \( \Delta P \), we can calculate the retentate pressure using the following equation:

\[ P_{\text{Retentate}} = P_{\text{atm}} + \Delta P \]

where \( P_{\text{atm}} \) is atmospheric pressure. \( \Delta P \) is the pressure drop across the pinch valve, which we calculated earlier. Since we're interested in gage pressure (pressure above atomospheric pressure), we can neglect \( P_{\text{atm}} \) and:

\[ P_{\text{Retentate}} = \Delta P \]

The relationship between feed rate (in mL/min), pinch valve position (from 0 to 1, 1 being fully open), and the retentate pressure is illustrated in the following plot:

Calculating Feed Pressure

Once we know the retentate pressure, we can calculate the feed pressure using the \(\text{Cv}\) value for the pass-through stream of the TFF filter and the mass flow rate, as set by the feed pump.

The \(\text{Cv}\) value represents the flow coefficient of the pass-through stream's filter section.

The equation for calculating the feed pressure \( (P_{\text{feed}}) \) is:

\[ P_{\text{feed}} = P_{\text{retentate}} + \Delta P_{\text{pass-through}} \]

Where \( \Delta P_{\text{pass-through}} \) is the pressure drop across the pass-through leg of the TFF filter. This pressure drop can be calculated using the calc_delta_p_psi() function, which takes in the mass flow rate and \(\text{Cv}\) value as parameters and returns \( \Delta P \) in psi.

Here is the relevant Python code snippet to compute \( P_{\text{feed}} \):

def calc_feed_pressure_psi(

self,

feed_rate_ml_min: float,

retentate_pressure_psi: float

) -> float:

"""

Calculate the feed pressure.

:param feed_rate_ml_min: Flow rate in the pass-through leg of the TFF filter (ml/min).

:type feed_rate_ml_min: float

:param retentate_pressure_psi: Retentate pressure (psi).

:type retentate_pressure_psi: float

:return: feed pressure (psi).

:rtype: float

"""

return retentate_pressure_psi + \

self.calc_delta_p_psi(feed_rate_ml_min, PressureModel.filter_cv_retentate)

Experimental measurements yield \(\text{Cv}_{filter} \approx 0.86\) for our Pelicon filter.

Calculating Permeate Pressure

Once we have the retentate and feed pressures, we can calculate the permeate pressure.

The formula for calculating the permeate pressure is based on the work by Juang et al., who used a resistance-in-series model to estimate the permeate flux in TFF systems.

The formula for the permeate flux \( Q_{\text{permeate}} \) is given by:

\[ Q_{\text{permeate}} = \frac{TMP}{\mu R_m} \]

where \( TMP \) is the transmembrane pressure, \( \mu \) is the fluid viscosity, and \( R_m \) is the total resistance of the membrane. We simplify the model by taking \(\mu R_m \) to be constant (experimental measurements yield \(\mu R_m \approx 0.8 \)).

The Python code snippet to compute \( Q_{\text{permeate}} \):

def calc_permeate_pressure(

feed_pressure_psi: float,

retentate_pressure_psi: float,

permeate_rate_ml_min: float

) -> float:

"""

Calculate the permeate pressure.

:param feed_pressure_psi: feed pressure (psi).

:type feed_pressure_psi: float

:param retentate_pressure_psi: Retentate pressure (psi).

:type retentate_pressure_psi: float

:param permeate_rate_ml_min: Permeate flow rate (ml/min).

:type permeate_rate_ml_min: float

:return: Permeate pressure (psi).

:rtype: float

"""

try:

avg_psi = (feed_pressure_psi + retentate_pressure_psi) / 2

return avg_psi - permeate_rate_ml_min * .8

except ZeroDivisionError:

return 0

The relationship between permeate rate (in mL/min), average input pressure \( \frac{ P_{\text{feed}} + P_{\text{retentate}} }{2} \) (in psi), and the permeate pressure is illustrated in the following plot:

Calulcate Balance Rates-of-Change

Finally, we update the simulated rates of change on the buffer, feed, and permeate balances using mass conservation.

Buffer Balance

- If a buffer pump is present, the flow rate (

ml/min) of the buffer pump is taken into consideration. - The ROC (

balance_rocs) for the buffer balance is determined by taking the negative of the flow rate of the buffer pump (buffer_pump_ml_min), simulating mass removal. - Optionally, this ROC is adjusted to simulate a deviation (

buffer_scale_error_pct) that may exist between the nominal flow rate of the pump and the actual mass removal rate from the buffer scale. The error term is added to 1 and then multiplied by the negative flow rate of the buffer pump.

Permeate Balance

- The ROC for the permeate balance is calculated based on the flow rate (

ml/min) of the permeate pump (permeate_pump_ml_min). - Optionally, this ROC is adjusted to simulate a deviation (

retentate_scale_error_pct) that may exist between the nominal flow rate of the pump and the actual mass addition to the permeate scale. The error term is added to 1 and then multiplied by the flow rate of the permeate pump.

Feed Balance

- The rate of change for the feed balance is calculated by summing the ROCs of the buffer and permeate balances.

- The sum is then negated to give the final ROC for the feed balance.

After all the ROCs are calculated, they are converted from ml/min to ml/s by dividing them by 60. These new rates are then set as the simulated rates of change for the balances in the system (self.balances.set_sim_rates_of_change(balance_rocs)).

Appendix

Model in Action

The following video snippet shows how the simulated pressure and weight values are bound to the independent process values. Modifying the pump's rates and changing the pinch valve position drive responses in the feed, retentate, and permeate pressures and the rates-of-change on the balances.

Full Code

To run the model, first install the application and then load the TFF - System setup (link here) in the application. Separately, execute the command:

python examples/models/tff.py -r 0

to run the model as an unregistered recipe.

Filename: examples/models/tff.py

import math

import time

import typing

from aqueduct.core.aq import Aqueduct

from aqueduct.core.aq import InitParams

from aqueduct.core.units import PressureUnits

from aqueduct.devices.balance import Balance

from aqueduct.devices.pressure.transducer import PressureTransducer

from aqueduct.devices.pump.peristaltic import PeristalticPump

from aqueduct.devices.valve.pinch import PinchValve

class PressureModel:

"""

This simple model estimates the pressures:

- feed (between feed pump and TFF feed input)

- retentate (between TFF retentate outlet and PV)

- permeate (between TFF permeate outlet and permeate pump)

using the current pump flow rates and pinch valve position

as input parameters.

Procedure:

1. model Cv of the pass through (feed-retentate) leg of the TFF filter using

P1 - P2 for known flow rates

2. model Cv of the pinch valve using a non-linear expression that decreases

as ~(% open)**-2 with an onset pct open of 0.3 (30%)

3. calculate retentate pressure assuming atmospheric output pressure and using Cv pinch valve

4. calculate feed pressure using retentate pressure and Cv TFF pass through

5. calculate permeate pressure using the expression for TMP

:ivar filtration_start_time: Start time of the filtration process.

:vartype filtration_start_time: float

:ivar filter_cv_retentate: Cv value of the retentate leg of the TFF filter.

:vartype filter_cv_retentate: float

"""

filter_cv_retentate: float = 0.87

@staticmethod

def cv_from_diameter_mm(diameter: float) -> float:

Cv = (((diameter / 1000) ** 2) * 0.61) * 46250.9

return Cv

@staticmethod

def cv_from_area_mm(area_mm: float) -> float:

# Convert the area from mm^2 to m^2

area_m = area_mm * 1e-6

# Calculate the diameter from the area

diameter_m = math.sqrt((4 * area_m) / math.pi)

# Calculate Cv using the given formula

Cv = (((diameter_m) ** 2) * 0.61) * 46250.9

return Cv

@staticmethod

def occluded_area_pct(delta_h: float) -> float:

"""

Calculate the percentage change in cross-sectional area of a tube when it's squeezed, based on the change in height.

See: https://www.hindawi.com/journals/mpe/2015/547492/

Parameters:

delta_h (float): The change in height due to the squeeze as a fraction of the original height (ranging from 0 to 1).

Returns:

float: The percentage change in the new cross-sectional area, scaled between 0 and 1.

1 indicates maximum occlusion (tube completely flat),

0 indicates no occlusion (tube retains original shape).

"""

x = max(0.5 - delta_h, 0)

oc = (

math.pi * x * (math.sqrt(-20 * x**2 + 12 * x + 3) / 6 - (2 * x / 3) + 0.5)

)

oc = min(-1 * (oc - 0.7853981633974483), 1)

return oc

@staticmethod

def calc_pv_cv(position: float) -> float:

"""

Calculate the Cv of the pinch valve.

:param PV: Pinch valve position.

:type PV: float

:return: Cv of the pinch valve.

:rtype: float

"""

response_zone = 0.35

if position < response_zone:

area = (math.pi * (5 / 2) ** 2) * (

1

- PressureModel.occluded_area_pct(

(response_zone - position) / response_zone

)

)

return PressureModel.cv_from_area_mm(area_mm=area)

else:

return 100

@staticmethod

def calc_delta_p_psi(mass_flow_rate_ml_min: float, cv: float) -> float:

"""

Calculate the pressure drop between through a restriction

using the metric equivalent flow factor (Kv) equation:

Kv = Q * sqrt(SG / ΔP)

Where:

Kv : Flow factor (m^3/h)

Q : Flowrate (m^3/h)

SG : Specific gravity of the fluid (for water = 1)

ΔP : Differential pressure across the device (bar)

Kv can be calculated from Cv (Flow Coefficient) using the equation:

Kv = 0.865 * Cv

:param mass_flow_rate_ml_min: Flowrate.

:type mass_flow_rate_ml_min: float

:param cv: Flow Coefficient.

:type cv: float

:return: Pressure drop (psi).

:rtype: float

"""

try:

kv = 0.865 * cv

# Convert mL/min to m^3/h

delta_p_bar = 1 / (kv / (mass_flow_rate_ml_min / 60.0)) ** 2

delta_p_psi = delta_p_bar * 14.5038 # Convert bar to psi

return delta_p_psi

except ZeroDivisionError:

return 0

@staticmethod

def calc_delta_p_rententate_psi(

feed_rate_ml_min: float, pinch_valve_position: float

) -> float:

"""

Calculate the pressure drop between retentate and atmospheric output

using the metric equivalent flow factor (Kv) equation:

:param feed_rate_ml_min: Flow rate in the pass-through leg of the TFF filter.

:type feed_rate_ml_min: float

:param pinch_valve_position: Pinch valve position.

:type pinch_valve_position: float

:return: Pressure drop between retentate and atmospheric outlet.

:rtype: float

"""

cv = PressureModel.calc_pv_cv(pinch_valve_position)

return PressureModel.calc_delta_p_psi(feed_rate_ml_min, cv)

def calc_feed_pressure_psi(

self, feed_rate_ml_min: float, retentate_pressure_psi: float

) -> float:

"""

Calculate the feed pressure.

:param feed_rate_ml_min: Flow rate in the pass-through leg of the TFF filter (ml/min).

:type feed_rate_ml_min: float

:param retentate_pressure_psi: Retentate pressure (psi).

:type P2: float

:return: P1 pressure.

:rtype: float

"""

return retentate_pressure_psi + self.calc_delta_p_psi(

feed_rate_ml_min, PressureModel.filter_cv_retentate

)

@staticmethod

def calc_permeate_pressure(

feed_pressure_psi: float,

retentate_pressure_psi: float,

permeate_rate_ml_min: float,

) -> float:

"""

Calculate the permeate pressure pressure.

https://aiche.onlinelibrary.wiley.com/doi/epdf/10.1002/btpr.3084

:param feed_pressure_psi: Feed pressure.

:type feed_pressure_psi: float

:param retentate_pressure_psi: Retentate pressure.

:type retentate_pressure_psi: float

:param permeate_rate_ml_min: Permeate flow rate.

:type permeate_rate_ml_min: float

:return: Premeate pressure (psi).

:rtype: float

"""

try:

avg_psi = (feed_pressure_psi + retentate_pressure_psi) / 2

return avg_psi - permeate_rate_ml_min * 0.8

except ZeroDivisionError:

return 0

def calc_pressures(

self,

feed_pump_ml_min: float,

permeate_pump_ml_min: float,

pinch_valve_position: float,

):

"""

Calculate and update the pressures using the model equations.

"""

retentate_pressure_psi = PressureModel.calc_delta_p_rententate_psi(

feed_pump_ml_min, pinch_valve_position

)

feed_pressure_psi = self.calc_feed_pressure_psi(

feed_pump_ml_min, retentate_pressure_psi

)

permeate_pressure_psi = PressureModel.calc_permeate_pressure(

feed_pressure_psi, retentate_pressure_psi, permeate_pump_ml_min

)

feed_pressure, retentate_pressure, permeate_pressure = (

min(feed_pressure_psi, 50),

min(retentate_pressure_psi, 50),

min(permeate_pressure_psi, 50),

)

return (feed_pressure, retentate_pressure, permeate_pressure)

class Model:

"""

This class manages the simulation model for a Tangential Flow Filtration (TFF) system.

It integrates various components such as feed, permeate, and buffer pumps, balances for

fluid levels, pressure transducers, and a pinch valve. It also contains methods to compute

derived values for these components based on real-time simulation parameters.

Attributes:

buffer_balance_index (int): Index for the buffer balance.

feed_balance_index (int): Index for the feed balance.

permeate_balance_index (int): Index for the permeate balance.

feed_transducer_index (int): Index for the feed pressure transducer.

permeate_transducer_index (int): Index for the permeate pressure transducer.

retentate_transducer_index (int): Index for the retentate pressure transducer.

buffer_scale_error_pct (float): Error percentage for the buffer scale.

retentate_scale_error_pct (float): Error percentage for the retentate scale.

pressure_model (PressureModel): An instance of PressureModel to handle pressure calculations.

"""

buffer_balance_index: int = 1

feed_balance_index: int = 0

permeate_balance_index: int = 2

feed_transducer_index: int = 0

permeate_transducer_index: int = 2

retentate_transducer_index: int = 1

buffer_scale_error_pct: float = 0.00001

retentate_scale_error_pct: float = 0.00001

pressure_model: PressureModel

def __init__(

self,

feed_pump: PeristalticPump,

permeate_pump: PeristalticPump,

buffer_pump: typing.Union[PeristalticPump, None],

balances: Balance,

transducers: PressureTransducer,

pinch_valve: PinchValve,

):

"""

Initialize the Model with given pumps, balances, transducers, and pinch valve.

Args:

feed_pump (PeristalticPump): The feed pump object.

permeate_pump (PeristalticPump): The permeate pump object.

buffer_pump (PeristalticPump or None): The buffer pump object or None.

balances (Balance): The balance object to manage fluid balances.

transducers (PressureTransducer): The pressure transducers.

pinch_valve (PinchValve): The pinch valve object.

"""

self.feed_pump = feed_pump

self.permeate_pump = permeate_pump

self.buffer_pump = buffer_pump

self.balances = balances

self.transducers = transducers

self.pinch_valve = pinch_valve

self.pressure_model = PressureModel()

def calculate(self):

"""

Calculate the derived values for all pressure transducers and balances.

"""

balance_rocs = [0, 0, 0, 0]

buffer_pump_ml_min = 0

# if BUFFER PUMP is present, use this to drive sim value balance

if isinstance(self.buffer_pump, PeristalticPump):

buffer_pump_ml_min = self.buffer_pump.live[0].ml_min

balance_rocs[self.buffer_balance_index] = (-1 * buffer_pump_ml_min) * (

1.0 + self.buffer_scale_error_pct

)

feed_pump_ml_min = self.feed_pump.live[0].ml_min

permeate_pump_ml_min = self.permeate_pump.live[0].ml_min

pv_position = self.pinch_valve.live[0].pct_open

balance_rocs[self.permeate_balance_index] = permeate_pump_ml_min * (

1.0 + self.retentate_scale_error_pct

)

balance_rocs[self.feed_balance_index] = -1 * (

balance_rocs[self.buffer_balance_index]

+ balance_rocs[self.permeate_balance_index]

)

# mL/min to mL/s

balance_rocs = [r / 60.0 for r in balance_rocs]

self.balances.set_sim_rates_of_change(balance_rocs)

(

feed_pressure,

retentate_pressure,

permeate_pressure,

) = self.pressure_model.calc_pressures(

feed_pump_ml_min, permeate_pump_ml_min, pv_position

)

self.transducers.set_sim_values(

[feed_pressure, retentate_pressure, permeate_pressure], PressureUnits.PSI

)

if __name__ == "__main__":

# Parse the initialization parameters from the command line

params = InitParams.parse()

# Initialize the Aqueduct instance with the provided parameters

aq = Aqueduct(

params.user_id,

params.ip_address,

params.port,

register_process=params.register_process,

)

# Perform system initialization if specified

aq.initialize(params.init)

# Set a delay between sending commands to the pump

aq.set_command_delay(0.05)

# Define names for devices

FEED_PUMP_NAME = "MFPP000001"

BUFFER_PUMP_NAME = "MFPP000002"

PERMEATE_PUMP_NAME = "MFPP000003"

BALANCES_NAME = "OHSA000001"

TRANSDUCERS_NAME = "SCIP000001"

PINCH_VALVE_NAME = "PV000001"

# Retrieve device instances

feed_pump: PeristalticPump = aq.devices.get(FEED_PUMP_NAME)

permeate_pump: PeristalticPump = aq.devices.get(PERMEATE_PUMP_NAME)

buffer_pump: PeristalticPump = aq.devices.get(BUFFER_PUMP_NAME)

balances: Balance = aq.devices.get(BALANCES_NAME)

transducers: PressureTransducer = aq.devices.get(TRANSDUCERS_NAME)

pinch_valve: PinchValve = aq.devices.get(PINCH_VALVE_NAME)

balances.set_sim_noise([0.0001, 0.0005, 0.0001])

transducers.set_sim_noise([0.0001, 0.0001, 0.0001])

# Create an instance of the PressureModel

model = Model(

feed_pump, permeate_pump, buffer_pump, balances, transducers, pinch_valve

)

# Continuous pressure calculation loop

while True:

model.calculate()

time.sleep(0.1)

Installation

Welcome to the Aqueduct application installation guide. This guide will walk you through the steps required to install the Aqueduct application on your system. Whether you are using Windows, Mac, or Linux, we have provided instructions to help you get started.

The installation process involves downloading the application, extracting the files, setting up Python, configuring the application settings, and then running the application. By following these steps, you'll have the Aqueduct application up and running in no time.

Let's get started with the installation process.

- Download the Application

- Extract the Application

- Locate the Executable

- Verify Python Installation

- Set Python Path

- Install aqueduct-py

- Run the Application

- Access the Application

- Explore the Application

Installation

Step 1: Download the Application

Download the latest release of the Aqueduct application. The application is available in the form of a ZIP archive.

Windows (64-bit)

- If you are using a Windows computer, download the

x86_64-pc-windows-gnuarchive.

Mac

-

If you are using a Mac computer with Intel-based Silicon, download the

x86_64-apple-darwinarchive. -

If you are using a Mac computer with Apple Silicon (M1 chip), download the

aarch64-apple-darwinarchive.

Linux

If you are using a Linux computer, choose the appropriate file based on your system architecture:

-

for ARM-based systems, download the

aarch64-unknown-linux-gnuarchive. -

for ARMv7-based systems, download the

armv7-unknown-linux-musleabihfarchive. -

for 64-bit Intel/AMD-based systems, download the

x86_64-unknown-linux-gnuarchive.

Step 2: Extract the Application

Extract the contents of the ZIP archive to a location of your choice on your local machine. The extracted directory will contain the necessary files and directories for running the application.

Note: The ZIP archive includes static assets used by the user interface (UI) of the application. These assets are required for the proper functioning of the UI.

Installation (continued)

Step 3: Locate the Executable

Navigate to the extracted directory and locate the executable file for your operating system. The filename may vary depending on the platform:

Windows

- Look for an executable file named

appwith the extension ".exe".

Mac

- Look for an executable file named

appwithout any file extension.

Linux

- Look for an executable file named

appwithout any file extension.

Step 4: Verify Python Installation

If you plan to use Python scripts within the Aqueduct application, ensure that Python is installed on your system and the Python executable is added to the system's PATH environment variable. This step is necessary to run Python scripts seamlessly within the Aqueduct application.

Windows

- If Python is not already installed, download and install Python from the official Python website (https://www.python.org). During the installation, make sure to check the box that says "Add Python to PATH" to automatically set the Python executable in the system's PATH.

Mac

- Python is usually preinstalled on macOS. Open a terminal window and enter the command

python3 --versionto check if Python is installed and accessible. If not, download and install Python from the official Python website (https://www.python.org).

Linux

- Python is typically available by default on most Linux distributions. Open a terminal window and enter the command

python3 --versionto check if Python is installed and accessible. If not, use your distribution's package manager to install Python.

Installation (continued)

Step 5: Set Python Path

Once you have verified that Python is installed and accessible, you need to set the Python path in the Aqueduct settings.toml file.

Note: The settings.toml file is created by the application the first time it is started.

Open the settings.toml file located in the extracted directory and find the [settings.recipe] section. Set the python_path variable to the absolute path of the Python executable on your system.

Windows

[settings.recipe]

python_path = "C:/Python310/python.exe"

Mac

[settings.recipe]

python_path = "/Library/Frameworks/Python.framework/Versions/3.9/bin/python3"

Linux

[settings.recipe]

python_path = "/usr/bin/python3"

If you're not sure where your Python executable is located, you can follow these steps to find it:

-

Windows:

- Open a Command Prompt window.

- Type

where pythonand press Enter. - The Command Prompt will display the path to the Python executable. Copy this path and use it as the

python_pathvalue in thesettings.tomlfile.

-

Mac:

- Open a terminal window.

- Type

which python3and press Enter. - The terminal will display the path to the Python executable. Copy this path and use it as the

python_pathvalue in thesettings.tomlfile.

-

Linux:

- Open a terminal window.

- Type

which python3and press Enter. - The terminal will display the path to the Python executable. Copy this path and use it as the

python_pathvalue in thesettings.tomlfile.

Step 6: Install aqueduct-py

Once you have set the Python path in the Aqueduct settings.toml file, the next step is to install the aqueduct-py package using pip. Follow these steps to install it:

- Open a terminal or Command Prompt window.

- Navigate to the directory where you extracted the Aqueduct application.

- Run the following command to install the

aqueduct-pypackage:

pip install aqueduct-py

- Wait for the installation to complete. Pip will download and install the necessary dependencies for the Aqueduct application.

Step 7: Run the Application

After setting the Python path, you can proceed with running the Aqueduct application.

Windows

- Double-click the executable file to launch the application

Mac

-

Open a terminal window and navigate to the extracted directory

-

Run the command

sudo chmod +x appto make the binary executable -

Run the command

./appto launch the application

Note for Mac Users: If you encounter a security warning when running the application, go to your System Preferences -> Security & Privacy and click the Open Anyway button to allow the application to run.

Linux

-

Open a terminal window and navigate to the extracted directory

-

Run the command

sudo chmod +x appto make the binary executable -

Run the command

./appto launch the application

Step 8: Access the Application

The Aqueduct application will start, and you can access it by opening a web browser and entering the following URL: http://127.0.0.1:5000 (assuming the default server settings are used). You should see the screen below in your browser.

If you need to change the server settings, refer to the "Server Settings" section in the settings.toml file located in the extracted directory. Update the IP address and port number according to your preferences before running the application.

Note for Mac Users: Apple AirPlay commonly utilizes port 5000. Therefore, if you come across any issues while accessing the application in your browser, it could be due to a port conflict. In such cases, you might want to consider changing the HTTP server port.

Step 9: Explore the Application

The Aqueduct web interface should now be accessible in your web browser. You can begin exploring the features and functionality of the application. The first time you run the Aqueduct application, it will create local directories for user files.

Runtime Application Settings

This README provides an explanation of the various settings available in the settings.toml file for the Aqueduct application.

Server Settings

-

[servers.http]ip(string): The IP address for the HTTP server. Default:127.0.0.1.port(unsigned integer): The port number for the HTTP server. Default: 5000.

-

[servers.ws]ip(string): The IP address for the WebSocket server. Default:127.0.0.1.port(unsigned integer): The port number for the WebSocket server. Default: 8080.

-

[servers.tcp]ip(string): The IP address for the TCP server. Default:127.0.0.1.port(unsigned integer): The port number for the TCP server. Default: 59000.

Application Settings

[settings.app]lab_recordable_limit(unsigned integer): The recordable limit for lab mode. Default: 10000000.sim_recordable_limit(unsigned integer): The recordable limit for simulation mode. Default: 1000000.sim_tick_ms(unsigned integer): The tick interval in milliseconds for simulation mode. Default: 100.

CAN Settings

[settings.can]interface(string): The interface name for CAN communication.

Database Settings

[settings.db]recordable_limit(unsigned integer): The recordable limit for the database. Default: 1000000.

Device Settings

[settings.devices]default_record(boolean): Determines if devices are recorded by default.timeout_ms(unsigned integer): The timeout duration in milliseconds for device communication. Default: 5000.round_trip(boolean): Specifies if round-trip communication is enabled. Round trip communications ensure that, where possible, connected devices respond to each command before the next command is sent.round_trip_attempts(unsigned integer): The number of attempts for round-trip communication before considering the transmission failed.

Recipe Settings

[settings.recipe]force_kill_on_queue(boolean): Specifies if an active recipe should be forcibly killed on queuing a new recipe. If set to true, no warning will be presented to the user to confirm killing the current recipe. Default: false.pause_on_queue(boolean): Determines if the recipe should be paused when queued. Default: true.python_path(string): The path to the Python executable. Default: `` (not set).

Serial Settings

-

[settings.serial.common]shared_bus(boolean): Specifies if the serial port is consideredshared, i.e. connected nodes shared a transmit data line.discovery_delay_ms(unsigned integer): The delay duration in milliseconds for device discovery.transmit_interval_ms(unsigned integer): The transmit interval in milliseconds for serial communication.baud_rate(unsigned integer): The baud rate for serial communication.rediscovery_interval_ms(unsigned integer): The interval duration in milliseconds for device rediscovery.rediscovery_duration_ms(unsigned integer): The duration in milliseconds for device rediscovery.

-

[[settings.serial.ports]]port(string): The serial port name.shared_bus(boolean): Specifies if the serial port shares a bus.discovery_delay_ms(unsigned integer): The delay duration in milliseconds for device discovery.transmit_interval_ms(unsigned integer): The transmit interval in milliseconds for serial communication.baud_rate(unsigned integer): The baud rate for serial communication.block(boolean): Prevent the application from looking for connected devices on this port.

WebSocket Settings

[settings.ws]live_interval_ms(unsigned integer): The interval duration in milliseconds at which live data is sent to connected clients. Default: 50.recordable_interval_ms(unsigned integer): The interval duration in milliseconds at which new recorded data is sent to connected clients. Default: 50.

Deployment Settings

[deployment]rpi(boolean): Specifies if the deployment is on a Raspberry Pi.secret_key(string): The secret key used for encrypting user session data.

Example settings.toml for Raspberry Pi with Aqueduct RS485 Hat

[servers.http]

ip = "127.0.0.1"

port = 5000

[servers.ws]

ip = "127.0.0.1"

port = 8090

[servers.tcp]

ip = "127.0.0.1"

port = 59000

[settings.can]

interface = "can0"

[settings.db]

path = "home/pi/aqueduct/local/app.db"

[settings.devices]

default_record = true

timeout_ms = 5000

round_trip = true

round_trip_attempts = 10

[settings.recipe]

force_kill_on_queue = true

python_path = "/usr/bin/python3"

[settings.serial.common]

shared_bus = true

discovery_delay_ms = 1000

transmit_interval_ms = 10

baud_rate = 57600

rediscovery_duration_ms = 15

[settings.ws]

live_interval_ms = 200

recordable_interval_ms = 200

[deployment]

rpi = true

# Enter your secret key here (64 characters long)

secret_key = "*******************"

systemctl_unit_name = "aqueduct.service"

Example settings.toml for Desktop Use

# HTTP server settings

[servers.http]

ip = "127.0.0.1"

port = 5000

# WebSocket server settings

[servers.ws]

ip = "127.0.0.1"

port = 8080

# TCP server settings

[servers.tcp]

ip = "127.0.0.1"

port = 59000

[settings.can]

interface = "can0"

[settings.db]

# Path to the database file

path = "local/app.db"

[settings.devices]

# Whether to record devices by default

default_record = true

# Timeout duration for device communication in milliseconds

timeout_ms = 5000

# Enable round-trip communication

round_trip = true

# Number of attempts for round-trip communication

round_trip_attempts = 5

[settings.recipe]

# Force kill the recipe when queued

force_kill_on_queue = false

# Path to the Python executable

python_path = "C:/Python310/python.exe"

[settings.serial.common]

# Whether the serial ports share a bus

shared_bus = false

# Delay duration for device discovery in milliseconds

discovery_delay_ms = 1000

# Transmit interval for serial communication in milliseconds

transmit_interval_ms = 5

# Baud rate for serial communication

baud_rate = 115200

# Interval duration for device rediscovery in milliseconds

rediscovery_interval_ms = 5000

# Duration of device rediscovery in milliseconds

rediscovery_duration_ms = 10

# Override the common serial port settings for COM5

[[settings.serial.ports]]

port = "COM5"

# block this port

block = true

# Override the common serial port settings for COM4

[[settings.serial.ports]]

port = "COM4"

# Override the common serial port baud rate

baud_rate = 9600

[settings.ws]

# Interval duration for live updates in milliseconds

live_interval_ms = 50

# Interval duration for recordable updates in milliseconds

recordable_interval_ms = 50

[deployment]

# Set to false for desktop deployment

rpi = false

# Enter your secret key here (64 characters long)

secret_key = "*******************"

Application Versions

- 0.0.8 - 2023-09-22

- 0.0.7 - 2023-09-22

- 0.0.6 - 2023-09-22

- 0.0.5 - 2023-09-22

- 0.0.4 - 2023-07-17

- 0.0.3 - 2023-07-12

- 0.0.2 - 2023-07-04

- 0.0.1 - 2023-06-19

[0.0.8] - 2024-03-04

Fixed

- fixed logging of datetime change by user and system shutdown events

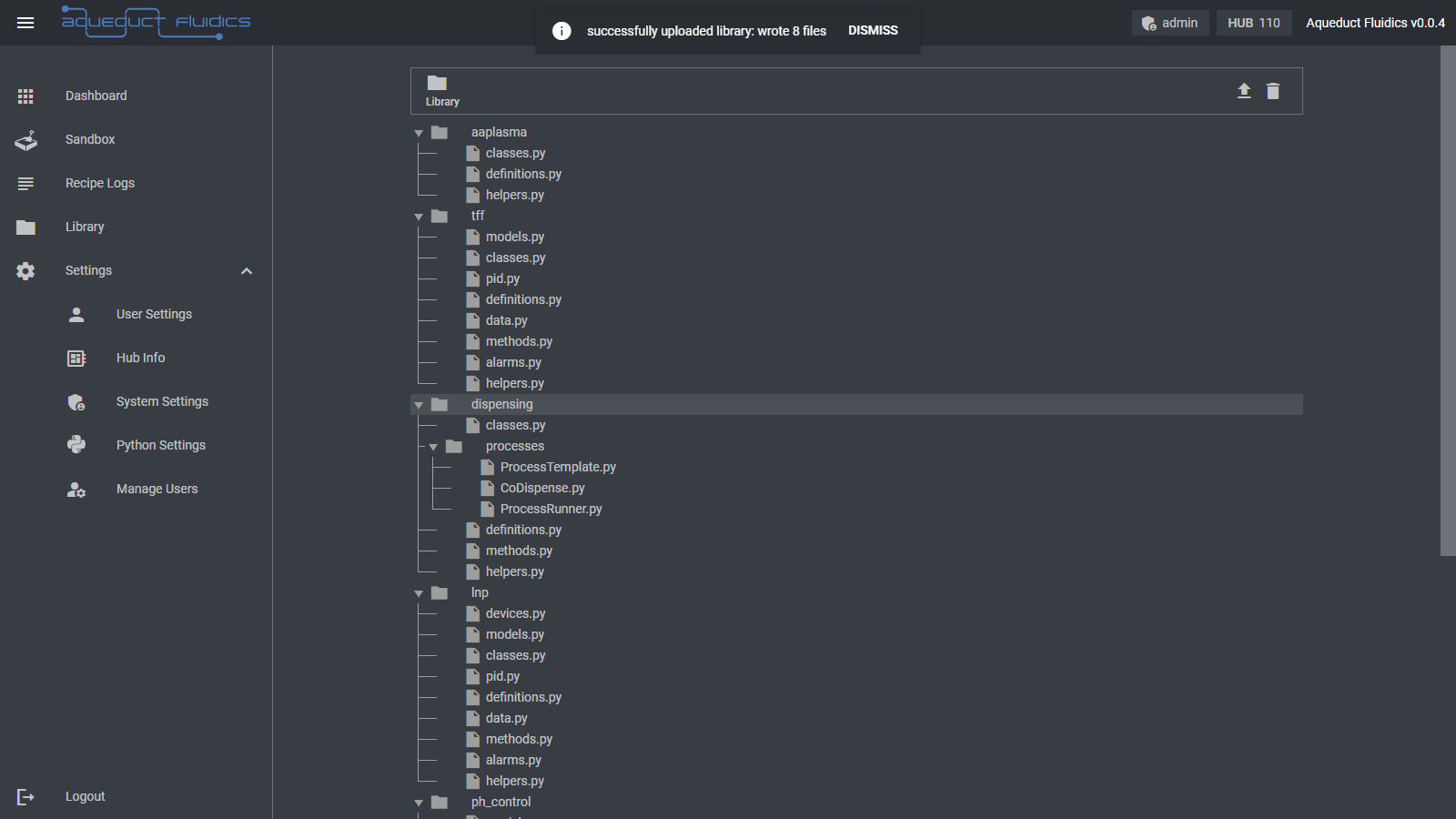

- allow other Mime types when uploading libraries

Added

-

New Feature: Added the ability to configure a server to ping for datetime information.

- Server IP address and port configurable in System Settings

Changed

[0.0.7] - 2024-02-21

Fixed

Added

Changed

-

reduced number of TRBD calibration points to 5, removed ninety degree calibration option

-

bumped Scichart version

[0.0.6] - 2023-11-15

Fixed

Added

-

added McFarland value to

optical_densitydevice -

updated Aqueduct TRBD device to include 10-point calibration for OD and McFarland values based on transmitted signal

Changed

[0.0.5] - 2023-09-22

Fixed

-

fixed connection creation for Pinch Valve device

-

fixed number incrementing/decrementing in controls for pumps and pinch valve position

Added

-

added jacketed vessel and vial icons

-

added

Upload SetupandUpload Recipeforms to the Sandbox Recipe Icon Menu and the Sandbox Widget Menu (Setup only) -

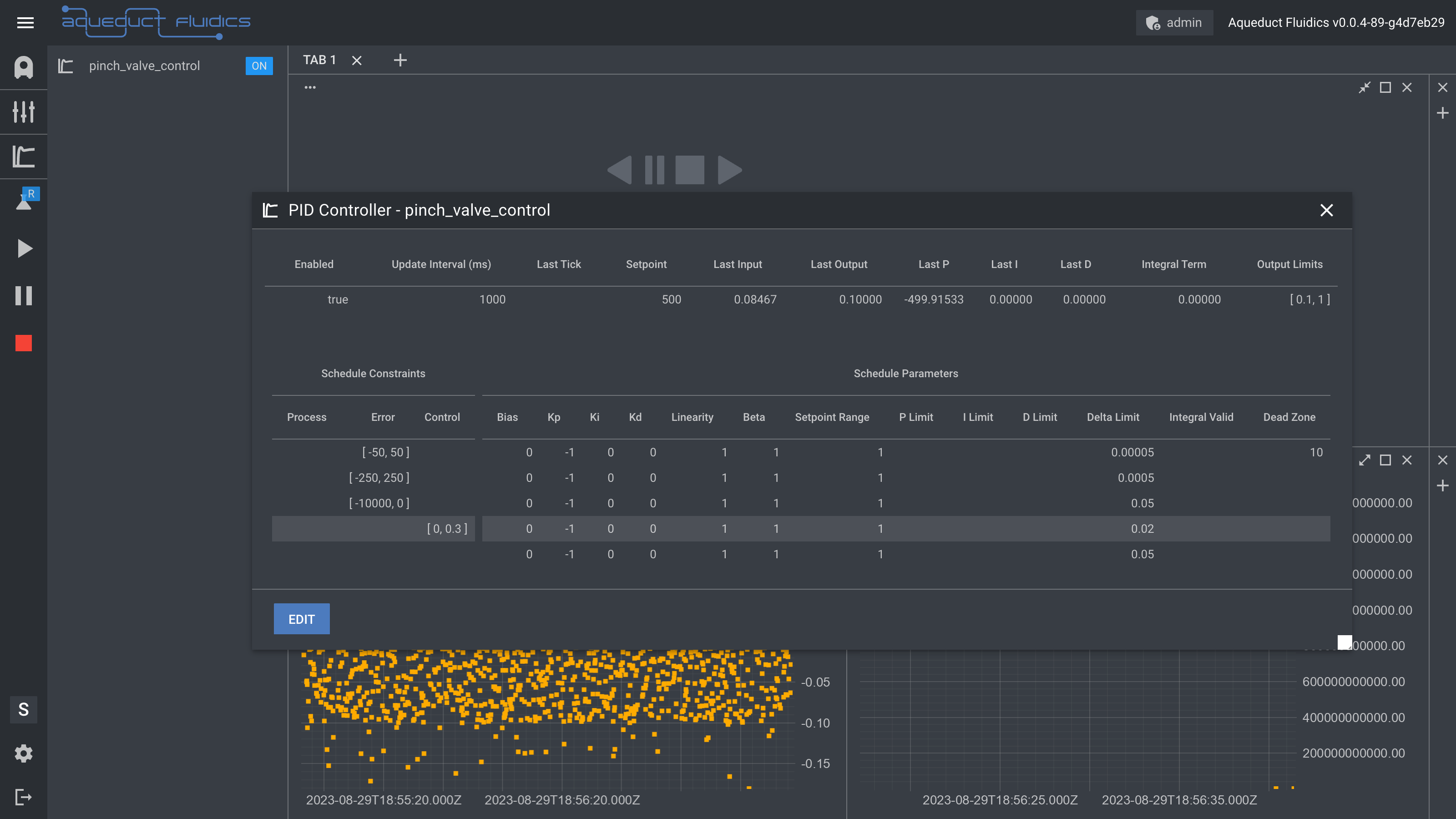

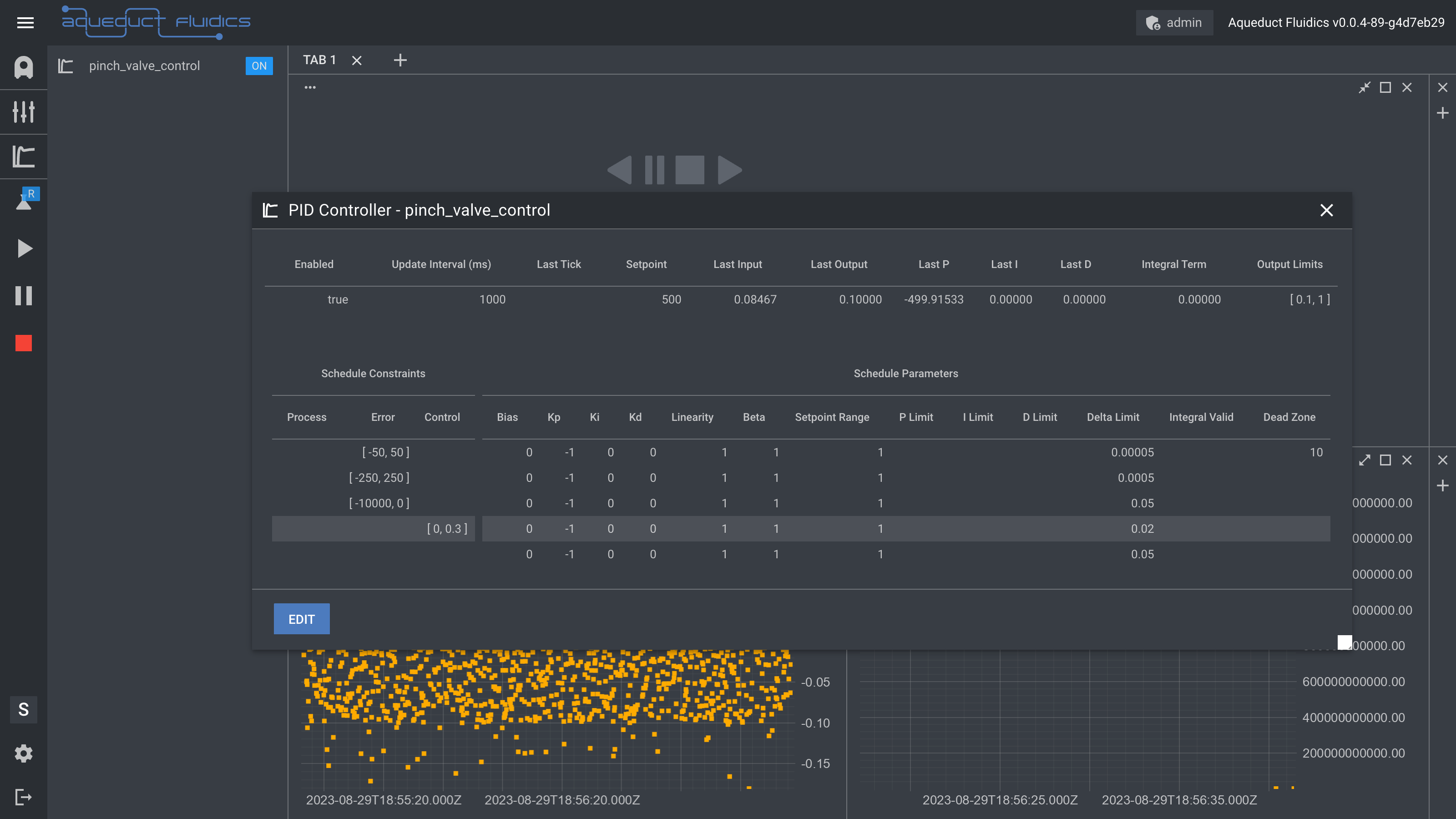

New Feature: Added PID-related classes and functions for advanced control.

- Introduced the

Pid,PidController,Schedule,Controller, andControllerScheduleclasses. - These classes enable more sophisticated control over processes, incorporating proportional-integral-derivative (PID) control strategies.

- The API now supports fine-tuning control parameters, setting schedules, and enabling/disabling PID controllers.

- Detailed documentation on these new features is available in the updated API documentation.

- Introduced the

-

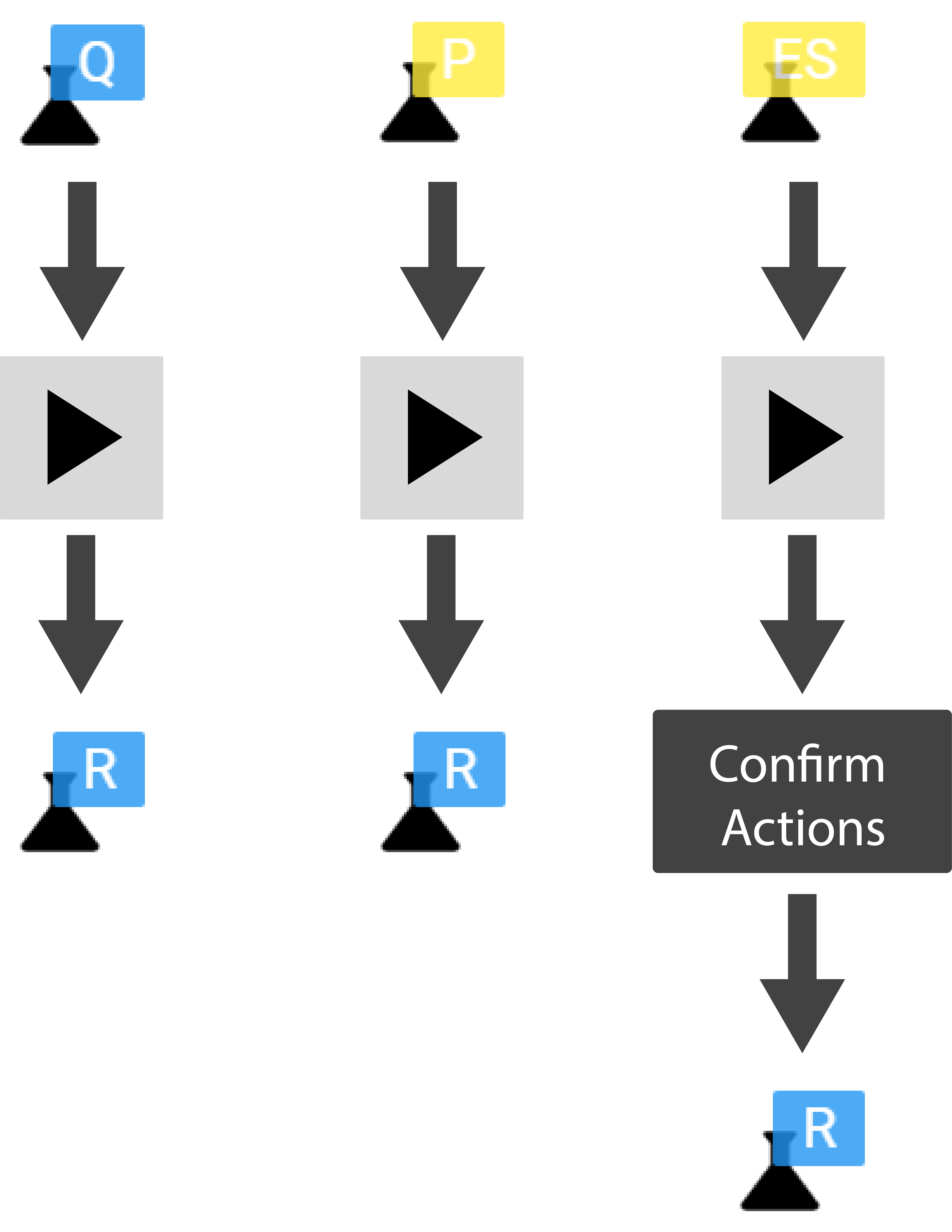

New Feature: Added the ability to control process registration during initialization.

- The new

register_processargument has been introduced to theInitParamsclass inaqueduct-py. - When initializing the system, you can now specify whether to register a process with the Aqueduct API.

- Registering a process installs UI-based recipe control, allowing users to perform actions like emergency stop (e-stop), pause, and resume for Python-based recipe processes.

- The

-ror--registercommand-line option is used to control this feature. - By default, if no value is provided for the

registeroption, it is set to1(true), meaning a process will be registered. - To skip process registration during initialization, explicitly set the

registeroption to0(false).

- The new

-

New Feature: Introduced the concept of a virtual device, designed to re-route actions sent from a client to a specified target.

- The

VirtualDevicemodule provides functionality for creating and managing virtual devices, which abstract multiple Device ID's to a single Node, eg. - This feature is especially useful for scenarios where the behavior of hardware devices needs to be simulated or redirected.

- The

-

Integration: Added support for the

aq-rpi-hallibrary.- The

aq-rpi-hallibrary provides hardware abstraction and control functions for Raspberry Pi-based systems. - This integration enables seamless interaction with hardware components and sensors using the Aqueduct API.

- The

Changed

- made Temperature Probe and Mass Flow Meter reading values optional

[0.0.4] - 2023-07-17

Fixed

- handle uploading empty files to library

Added

Changed

-

"continue" buttons disabled until "set" pressed when calibrating MasterFlex pumps

-

changed PPX (TMCM6214) firmware to use a 10 ms delay bewteen pings for position

-

added "plain" text files as allowed subtype for library upload with .py extension

[0.0.3] - 2023-07-12

Fixed

Added

-

added frequency scaling calibration for single (TMC5130) Aqueduct peristaltic pump

-

added loading of stored frequency scaling from EEPROM for single (TMC5130) Aqueduct peristaltic pump

-

added viewing of library files in browser

-

PH3 (3x pH probe) firmware

Changed

[0.0.2] - 2023-07-04

Fixed

-

Bound on TriContinent syringe pump plunger position to eliminate updating during a plunger resolution mode change.

-

Fixed timing on valve acutation queries for TRCX firmware

-

SciChart licensing

Added

-

added PH3 firmware, refactored TRBD device to use 3 x I2C main

-

added pH probe set calibration command and action

Changed

-

UI modifications

-

updated border width calculation for widget/container windows when full size

-

added context menu interactions for toggling/clearing recorded values and setting sim params

-

-

made status update pH value field for pH device field optional

-

Noneupdate of torr values for SciLog pressure transducers and grams values for Ohaus balances. This change will set the values toNonewhen no device is attached to the node.

[0.0.1] - 2023-06-19

Initial Release

Quick Start to the Aqueduct User Interface

The Aqueduct User Interface is a digital playground where you can configure your equipment, visualize and interact with your process or protocol, script and save recipes, and control the execution of your recipes.

Features of the Aqueduct User Interface

-

Setup Configuration: Build your setup by selecting and configuring devices, containers, and connections from the Aqueduct library. This allows you to customize your equipment setup according to your experimental requirements.

-

Simulated and Laboratory Environments: Visualize and interact with your process or protocol in both simulated and laboratory environments. The simulated environment allows you to test and validate your setup and recipe before running experiments in the actual laboratory.

-

Recipe Management: Create and save recipes that automate your process. Recipes are scripts that define the sequence of actions, such as controlling device operations and managing container contents. This allows you to easily reproduce your experimental procedures.

-

Control and Execution: Control the execution of your active recipe. Start, pause, resume, and stop the execution of your recipe to have fine-grained control over your experimental process.

Quick Start Guide

This Quick Start guide is intended to serve as an introduction to the Aqueduct User Interface by proceeding through the steps required to create a simple Recipe. The Recipe, which will use only a single peristaltic pump and two containers, is not particularly useful, but the process will demonstrate the basics of creating a Setup and scripting a Recipe with the Setup's devices and then familiarize you with the interface's interactions and terminology.

Let's get started...

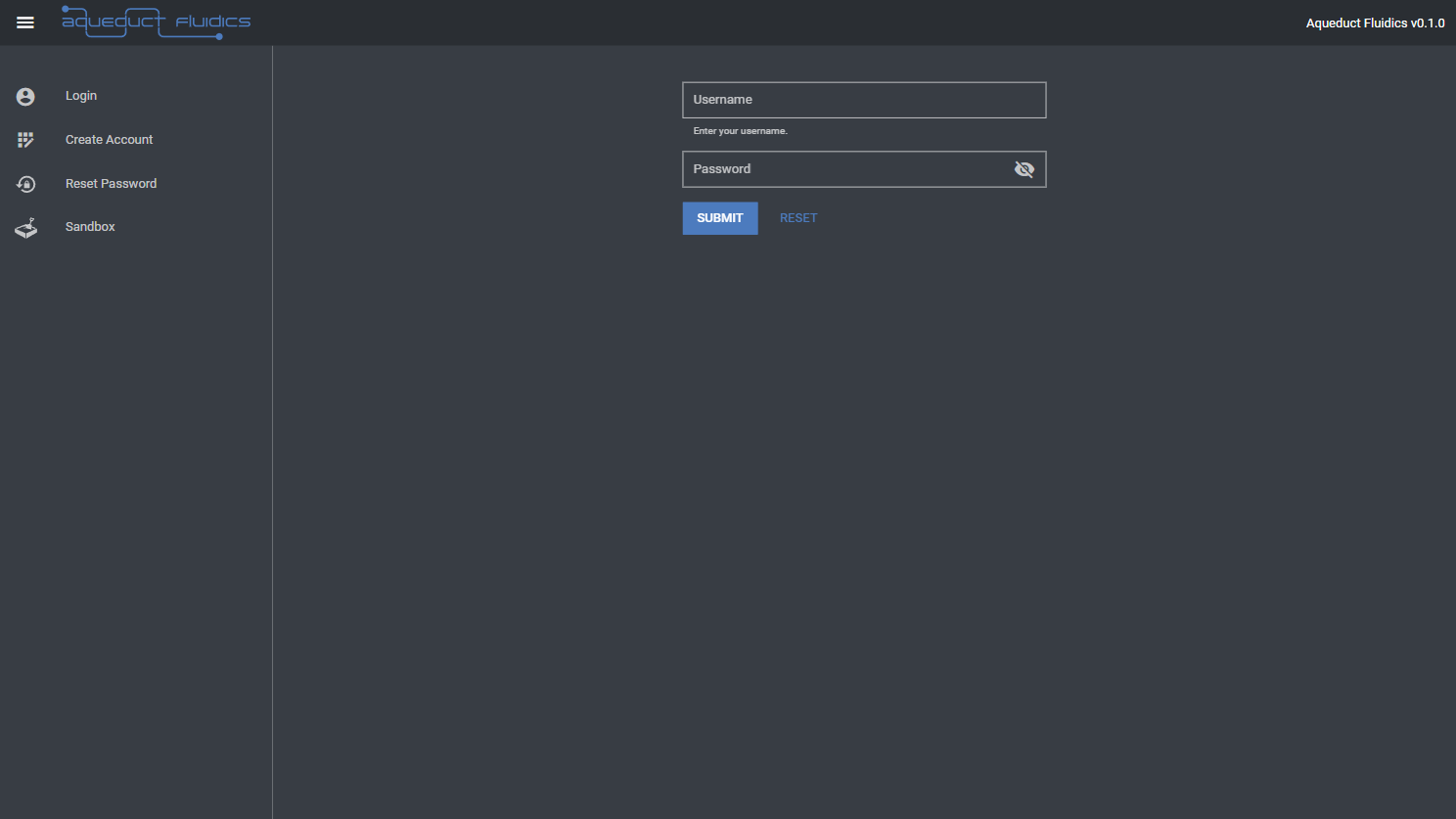

Login

The Login page in the Aqueduct dashboard allows you to securely access your account and manage your Aqueduct system.

Logging into the Dashboard

-

Open a web browser on your computer.

-

In the address bar, enter the URL for the Aqueduct Dashboard. The default URL is

http://127.0.0.1:5000, assuming you are running Aqueduct on the local machine. If you have customized the server settings, please use the appropriate IP address and port number. -

Press Enter or Return to load the Aqueduct Dashboard login page.

-

On the login page, you will see a login form.

-

Enter the following credentials to log in:

- Username: admin

- Password: password

-

After entering the credentials, click the

Submitbutton. -

If the provided credentials are correct, you will be logged into the Aqueduct Dashboard and redirected to the main dashboard interface.

-

You can now explore the various features and functionality offered by the Aqueduct Dashboard, such as managing recipes, monitoring devices, and accessing logs.

-

To log out of the Aqueduct Dashboard, look for the

Logoutbutton located at the bottom of the left side menu.

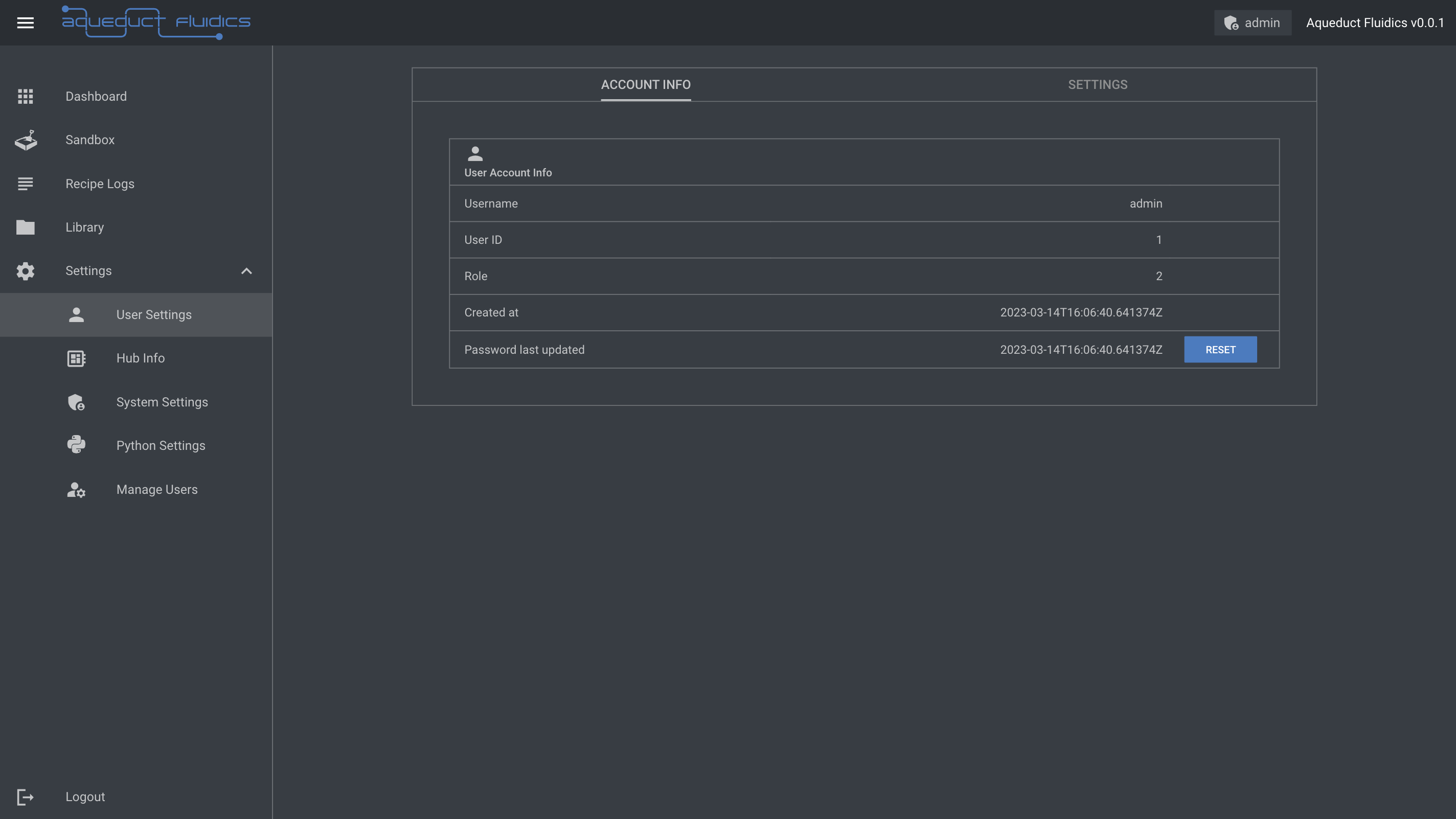

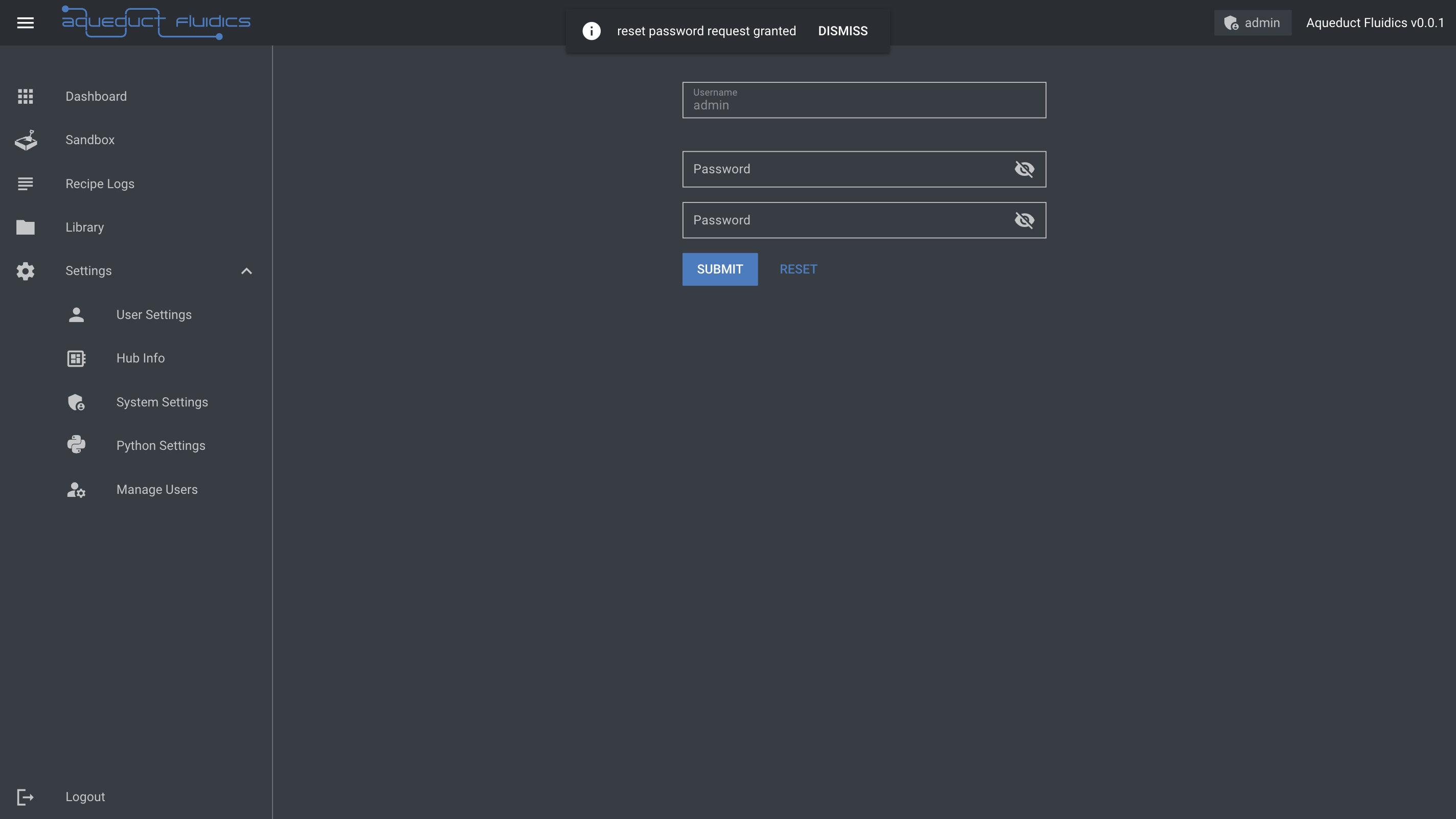

Please note that it is highly recommended that you change the default password for the admin user after the initial login. See the User Settings page for instructions on how to change your password.

Dashboard Overview

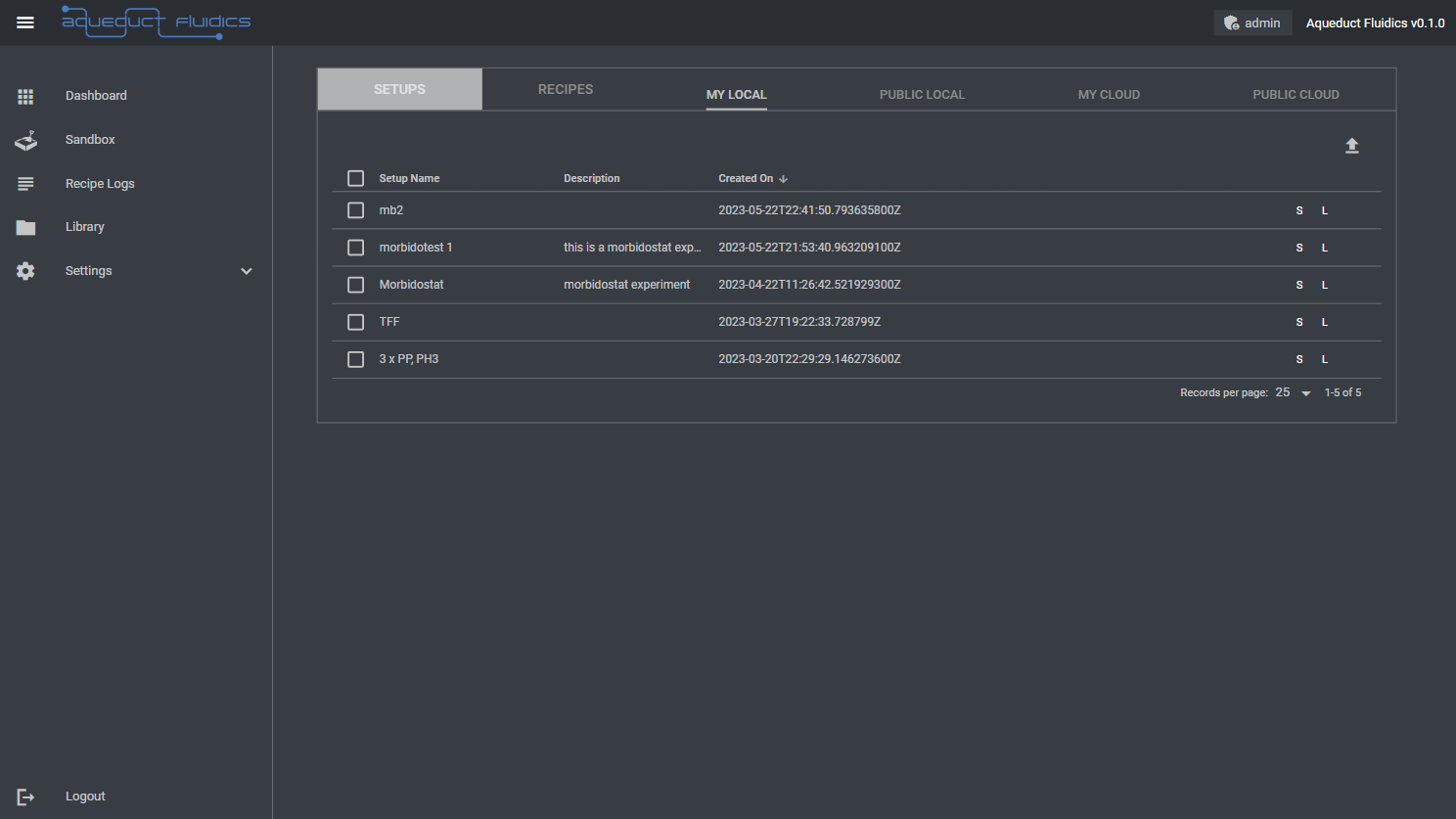

The Dashboard page allows you to access user and public setups and recipes. The page is organized into two tabs: Setups and Recipes. Each tab displays a table with the following columns:

- Model Name: The name of the setup or recipe.

- Description: Brief description or details of the setup or recipe.

- Created On: The date and time when the setup or recipe was created.

- Actions: Provides options to activate the model in simulation or lab mode, edit the model, or delete the model.

Setups or Recipes Tabs

The Setups or Recipes tab displays a table of models available in your Aqueduct application. The models are categorized into four subtabs:

- My Local: Setups or Recipes created by you.

- Public Local: Setups or Recipes shared publicly by other users.

- My Cloud: [Cloud access to setups is currently under development and not functional.]

- Public Cloud: [Cloud access to setups is currently under development and not functional.]

Accessing Models

To access setups or recipes:

-

Select the appropriate tab (Setups or Recipes) based on the model type you want to access.

-

Within the selected tab, click on the desired subtab (My Local, Public Local, My Cloud, or Public Cloud) to choose the source of the model you wish to access.

-

Locate the table row corresponding to the model you want to access.

-

Use the action buttons in the Actions column to perform specific actions on the model. These actions include activating the model in simulation or lab mode, editing the model, or deleting the model.

Please note that the availability and accessibility of models may vary based on your user permissions and the configurations set by the model authors.

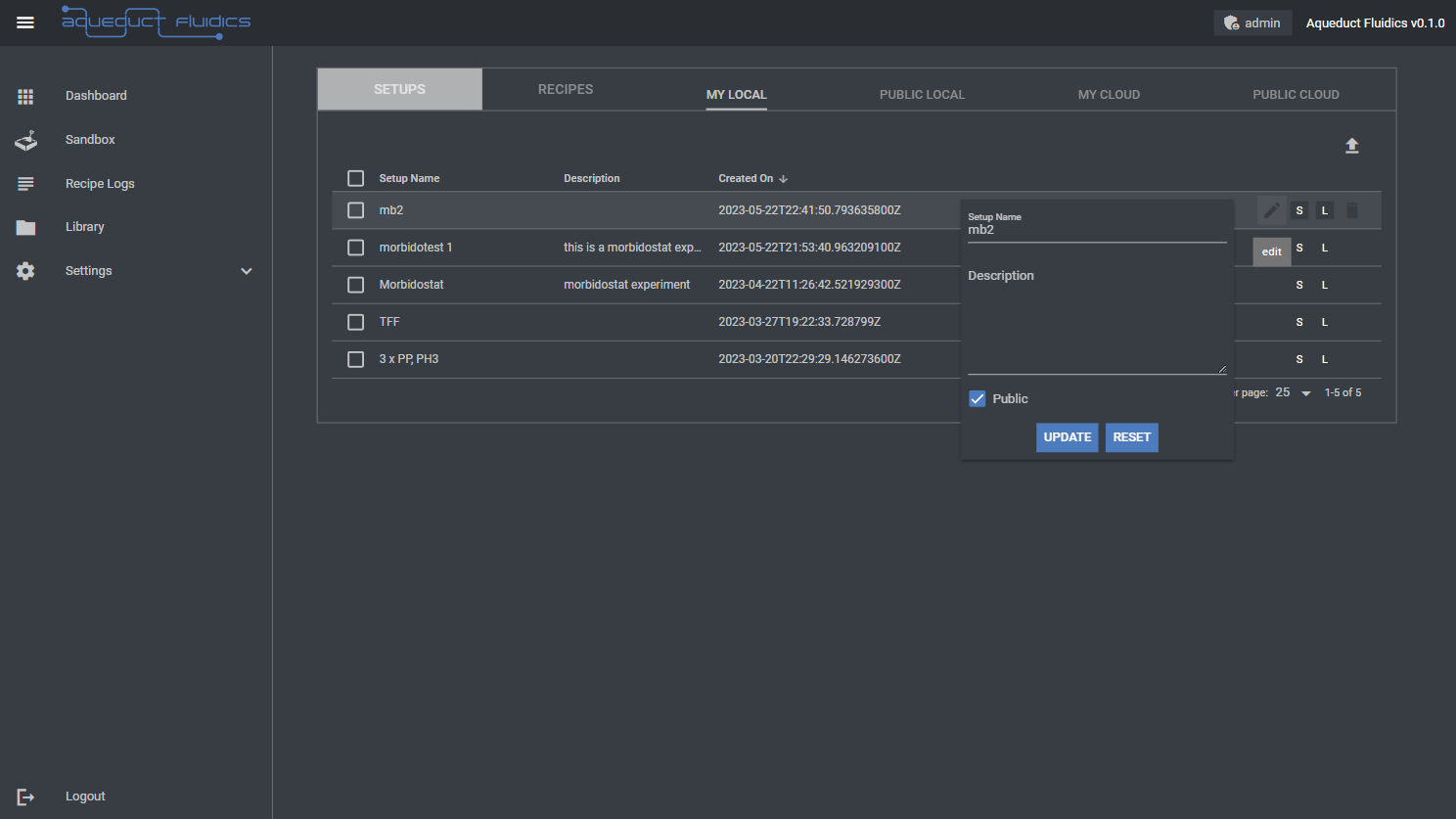

Editing Setups and Recipes

Click the pencil icon in the respective row to edit the item's details. This allows you to update the name, modify the description, or change the visibility settings of the setup or recipe.

Downloading Setups and Recipes

To download a model (setup or recipe) from the table, select the row associated with the model and click the download icon at the top right of the table. You can download a single model with the .setup or .recipe extension or multiple models archived as a .zip file. This allows you to save the model file to your local machine for further use or backup.

Uploading Setups and Recipes

To upload a model (setup or recipe) to the dashboard, click the Upload Icon button located at the top right of the table. This opens a file selection dialog where you can choose the model file (in the appropriate format) from your local machine and upload it to the dashboard. Once uploaded, the model will be available in the corresponding table. The model must have the appropriate extension (.setup or .recipe) and will be validated by the application to ensure the correct content.

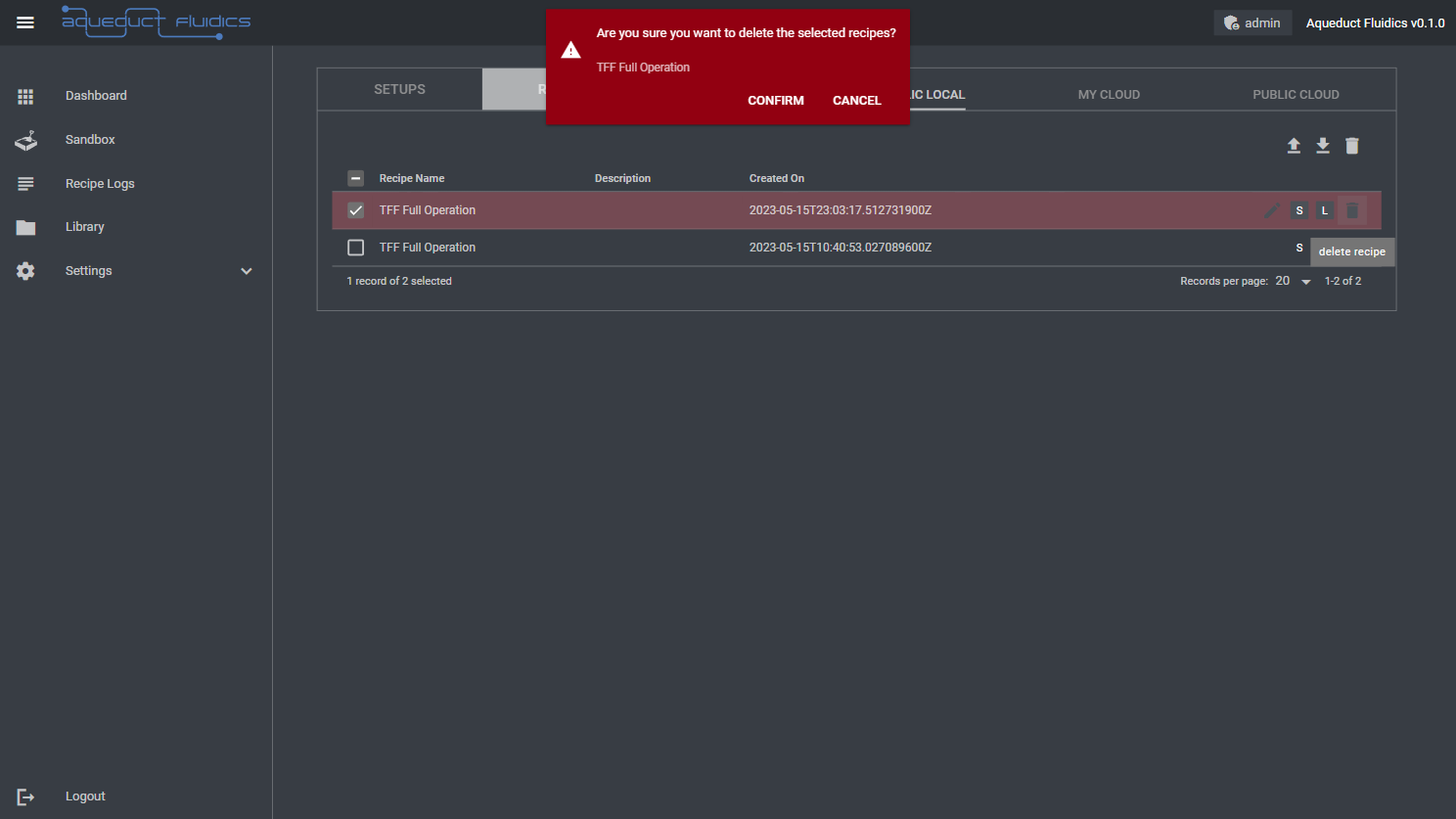

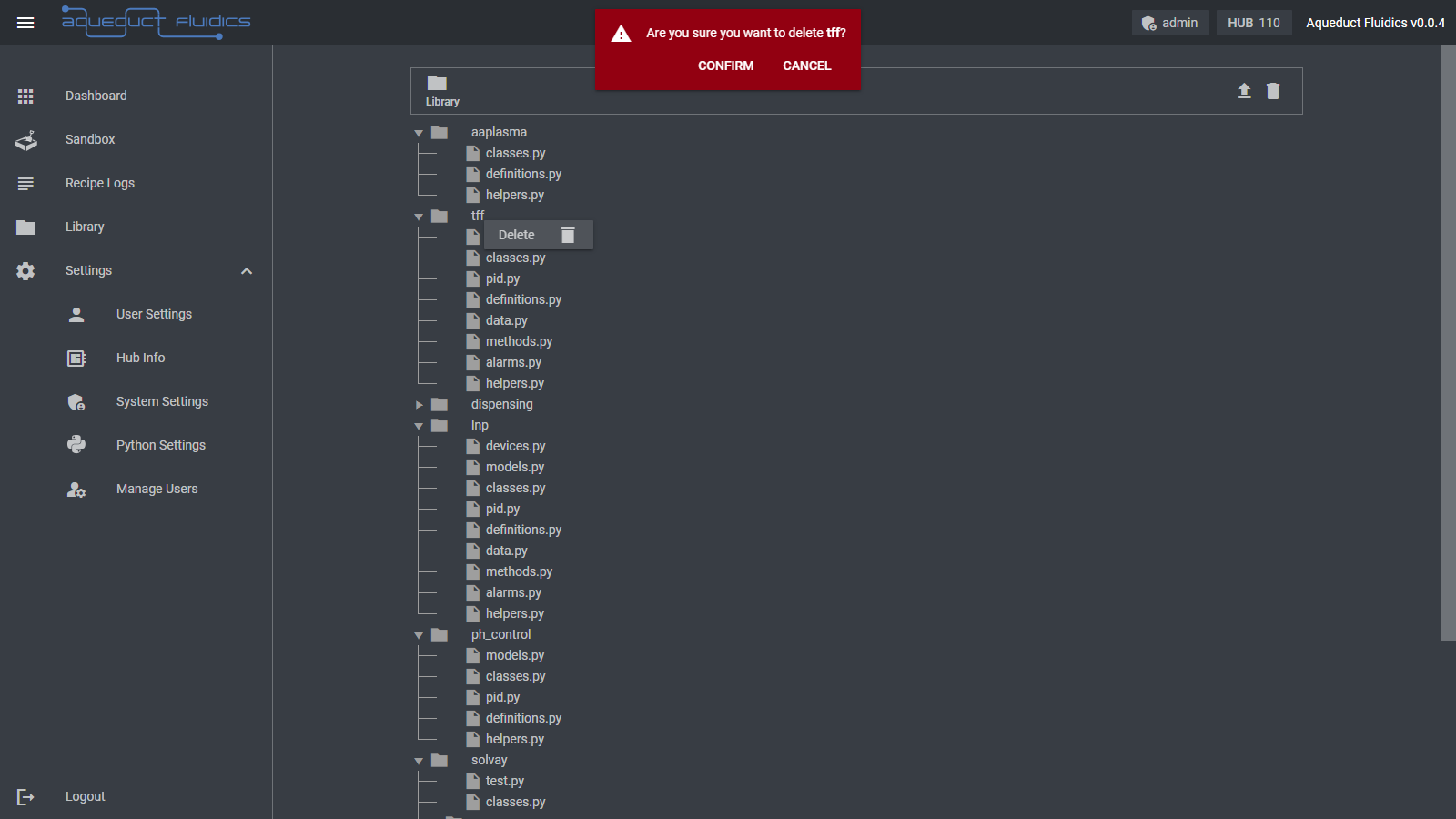

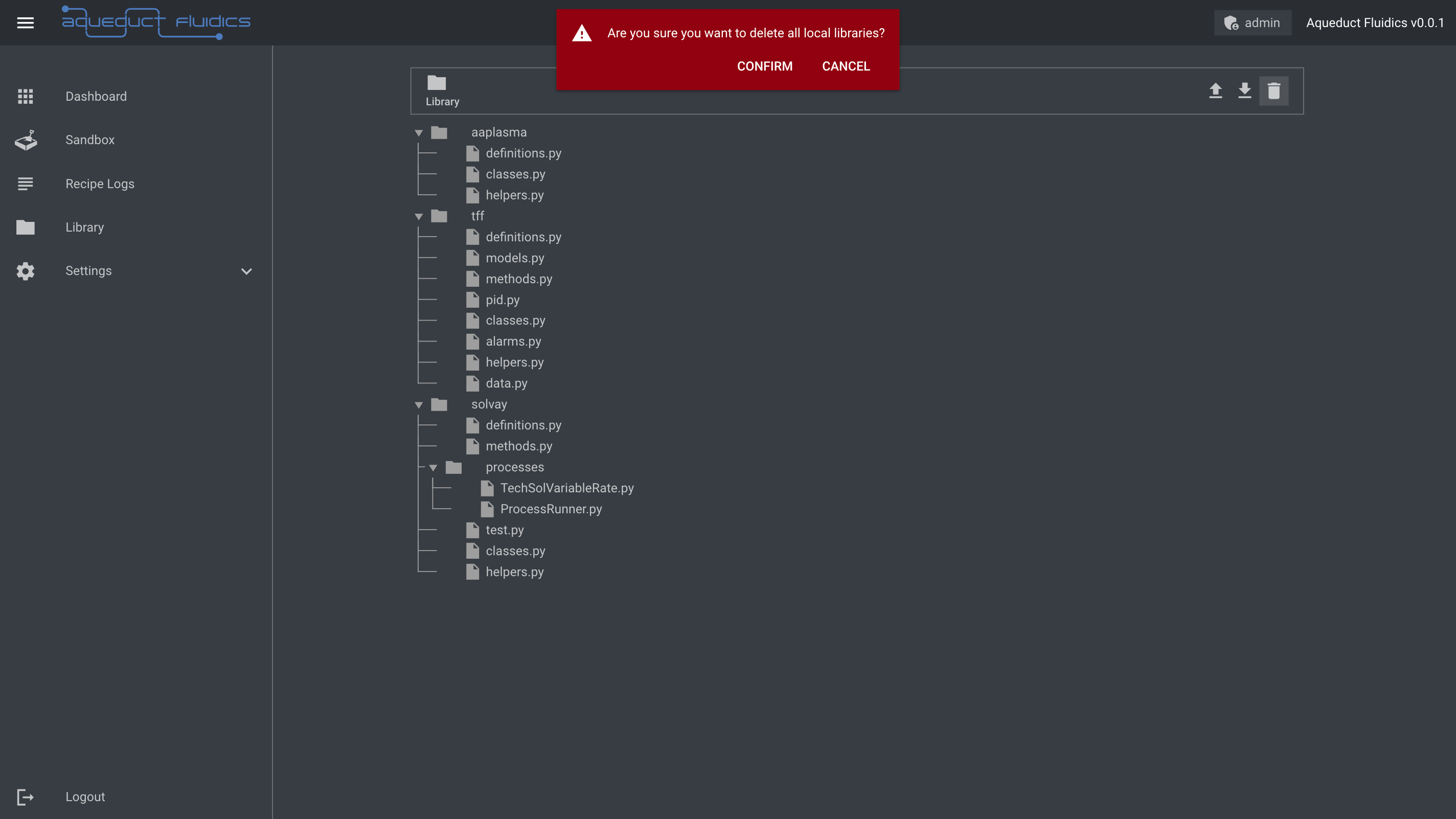

Deleting Setups and Recipes

To delete one or more models (setups or recipes) from the table, click the rows associated with the models and then click the delete icon at the top right corner of the table. You will be presented with a confirmation popup to confirm that you want to delete the selected models. This action permanently removes the models from the dashboard, so ensure that you have the necessary backups or copies if you wish to retain the models.

Sandbox Overview

The Sandbox page allows you to interact with your setup. It facilitates:

Device Interaction

- Access and control individual devices in your setup.

- Adjust settings, start or stop operations, and monitor parameters.

- Simulate device actions and observe real-time effects.

Recipe Execution

- Load and execute saved recipes.

- Observe how devices, containers, and connections interact based on defined steps.

- Test and validate recipes before real laboratory execution.

Data Monitoring

- Monitor and record data generated by devices during Sandbox interactions.

- Visualize data in real-time graphs for trend analysis and pattern identification.

- Make data-driven decisions to optimize process performance.

Window Arrangement and Adding a Device

We'll begin our introduction to the Sandbox by rearranging the main window workspace.

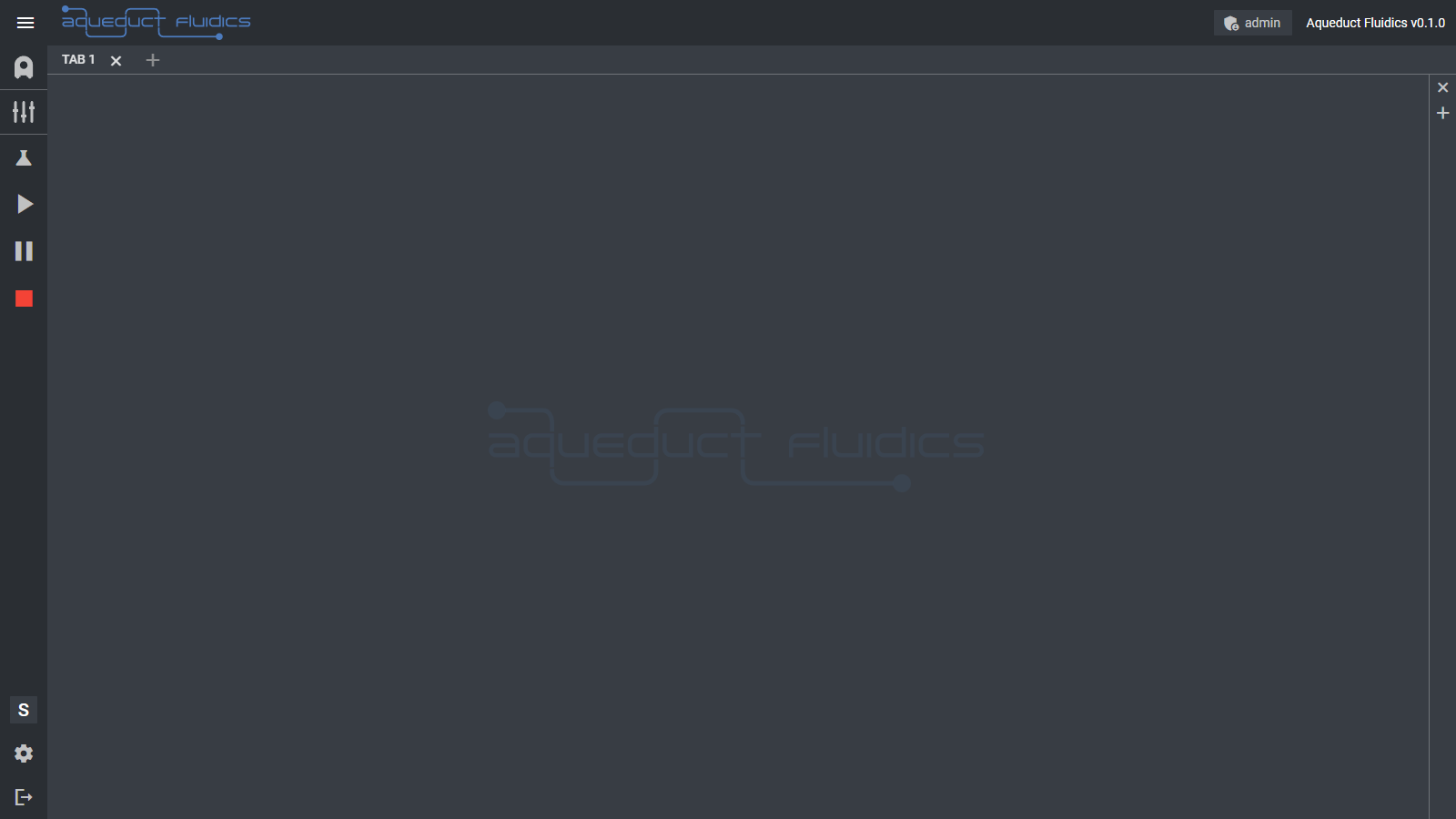

If you see a faint Aqueduct Fluidics logo on a white canvas, it means that you have an empty Tab; no Tab Containers or Widgets have been added to it yet.

Each workspace Tab can contain one or more Tab Containers. Each Tab Container can contain one or more Widgets.

Nesting Widgets in Tab Containers and Tab Containers in Tabs gives you the flexibility to organize the interface's layout to suit your application and personal preferences.

Let's add a Tab with a single, empty Tab Container to the workspace by clicking the plus icon just to the right of the left sidebar menu. Next, add a Widget to the new Tab Container by clicking the plus icon on the vertical Tab Container menu at the right of the screen. We want to add a Sandbox Widget, so click:

> Add Widget > Sandbox

The Sandbox Widget displays cartoon icons of all of the Devices, Containers, and Connections in your Setup. The icons have interactive buttons and animate to indicate activity.

Now we're ready to add a Device to our Setup, which is currently empty.

Before continuing, make sure that you're in Simulation Mode by verifying that the Mode Indicator badge on the lower left sidebar menu displays an S. If you see an L, you're in Lab Mode. Switch to Sim Mode by clicking the Settings Button (gear icon) below the badge and selecting:

> Mode > Sim

To add a Device, expand the Setup menu by clicking the Setup Menu Toggle (pump icon) on the left sidebar menu. Click the plus icon to the right of the Devices expansion menu to reveal the Device Library, which is organized by device function. Select:

> Pumps > Peristaltic Pump (PP)

to add a PP Device. A new PP Icon will appear in the Sandbox Widget and a new peristaltic_pump_000001 entry will appear in the Devices expansion menu. By default, each Simulated device is assigned the name:

[TYPE]_[NUMBER]

when it's added to the Setup, so our first peristaltic_pump type Device gets the name peristaltic_pump_000001.

We'll see how to change the name later.

You can also add a Device from the context (right click) menu in the Sandbox Widget. Right click in the widget, and then select:

Add Component > Device > Pumps > Peristaltic

to add a second peristaltic pump. We don't actually want this pump, so you can go ahead and delete it by right clicking on the icon and selecting:

Delete Device

Ok, we have a pump. Now let's see how to interact with it...

Device Control

Let's see how to control the peristaltic pump device that we've just added to our Setup.

Reveal the controls for the peristaltic pump device by clicking:

Devices > peristaltic_pump_000001 > Controls

from the Setup Menu on the left sidebar menu. You'll see some control buttons

(reverse, pause, stop, and forward), readouts for the pump's speed in mL/min and a

counter for the volume of liquid displaced, mL pumped.

Below a horizontal line are inputs for parameters that control the pump's operation. There are inputs

for a rate value, a dropdown to select the rate units, a toggle to select whether to

run the pump continuously or for a finite volume, and an input to enter an optional

finite value and finite units if finite mode is selected. For instance, if you wish to run the

pump for a defined number of milliliters or number of seconds, you would use finite mode.

Enter 10 in the field for mL/min and click the right (forward) arrow to start the pump.

The pump is now operating continuously in the clockwise direction at 10 mL/min. You should

see the mL pumped display counter increase with time as the pump displaces more (simulated)

liquid.

When you're ready to stop the pump, press the stop button. You should see the rollers on the

icon stop rotating and the mL/min display in the control window reset to 0 mL/min.

Next, click the left (reverse) arrow to start the pump in the opposite direction. Again, the

mL pumped display counter increases with time as the pump continues to run.

You probably noticed that there are also buttons above the peristaltic pump Icon in the Sandbox Widget. If they're not visible, toggle control visibility by opening the Sandbox context menu (right click) and select:

Display > Controls > Show

These buttons function in the same way as the buttons in the Control Panel and will use the

same parameters that are entered in the Panel. Let's use these buttons to run the pump for

1 milliliter in the forward direction at 10 mL/min. Toggle the vertical mode selector to finite, enter

10 in the units entry and make sure that mL is selected in the dropdown.

Now, press the forward button above the peristaltic pump icon in the Sandbox Widget.

Again, the pump will start running, but you'll notice that once the mL pumped display

reaches 1 milliliter, the pump will stop.

Summary: Device Interactions in the Aqueduct User Interface

The Aqueduct User Interface provides a consistent and intuitive approach to interact with devices. Whether you are controlling a peristaltic pump, a temperature controller, or any other device, the following key points summarize the device interactions in the Aqueduct User Interface:

-

Accessing Device Controls: Navigate to the Devices section in the Setup Menu on the left sidebar. Expand the device of interest to reveal the sub-menu, and click on Controls to access the specific controls and parameters for that device.

-

Inputting Device Parameters: Adjust the device's parameters using the provided controls, buttons, and input fields. Common parameters include rate values, unit selections, mode toggles (continuous or finite), and optional finite values and units.

-

Multiple Nodes per Device: In some cases, a device may have multiple nodes associated with it, such as multiple channels in a peristaltic pump. A master node controls the operation of all associated nodes. Starting or stopping the master node synchronizes the actions across all nodes within the device.

-

Sandbox Icon Buttons and Parameters: The Sandbox Widget allows direct device control. Right-click on the Sandbox Widget to access the context menu and select Display > Controls > Show to reveal the buttons associated with each device icon. These buttons function the same way as the controls in the Setup Menu and utilize the parameters entered in the Controls section.

When you're finished running the simulated pump actions, move on to the the next step, where we'll add some Containers and Connections to help us visualize and document the Setup.

Add Containers and Make Connections

So now we have a pump that we can run clockwise or counterclockwise for an indefinite (continuous) or finite duration. Next, let's add some Containers - simulated vessels - to serve as a source and sink for the pump to transfer liquid from/to.

Why add Containers? You certainly don't need to, and you can script Recipes with only Devices, but Containers (and Connections, which are coming next) can be a helpful visualization tool for recreating a Setup in the lab and for intuiting your Setup in the Sandbox.

Adding a Container follows the same steps as adding a Device. Expand the Setup menu by clicking the Setup Menu Toggle (pump icon) on the left sidebar menu. Click the plus icon to the right of the Containers expansion menu to reveal the Container Library. Select:

> Containers > Bottles > 100 mL Bottle

to add a new 100 mL bottle to the setup. A new Bottle Icon will appear in the Sandbox Widget and a new 100 mL bottle entry will appear in the Containers expansion menu. By default, each container is assigned its type (100 mL bottle, in this case) as its name when it's added to the Setup.